Product Documentation

- Brochures

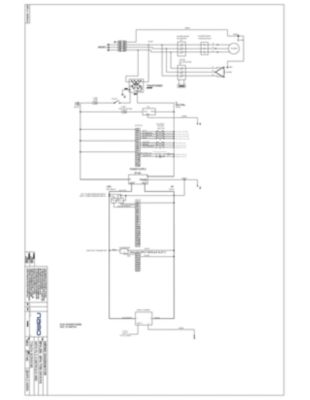

- Electrical Diagram

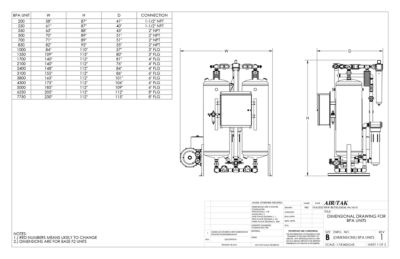

- GA Drawing

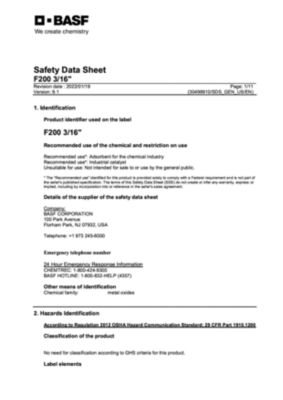

- Material Safety Data Sheets

- User Guides

Technical Data by Model

Dryer Models |

Recommended Pre & After Filtration |

Inlet & Outlet |

Rated Flow at 100 psig |

Heater |

|

|---|---|---|---|---|---|

Pre-Filter |

After-Filter |

NPT (F)/FLG |

scfm |

kW |

|

GF 0325 M01 |

NHT 0300 M1 |

1 ½" |

200 |

6 |

|

GF 0450 M01 |

NHT 0450 M1 |

2" |

250 |

6 |

|

GF 0700 M01 |

NHT 0650 M1 |

2" |

350 |

9 |

|

GF 0700 M01 |

NHT 1000 M1 |

2" |

500 |

12.5 |

|

GF 0850 M01 |

NHT 1000 M1 |

2" |

700 |

12.5 |

|

GF 1250 M01 |

NHT 1000 M1 |

3" |

850 |

15 |

|

GF 1500 M01 |

NHT 1600 M1 |

3" |

1000 |

18 |

|

NFZ 2500 M01 |

NFZ 2500 M1HT |

4" |

1350 |

25 |

|

NFZ 2500 M01 |

NFZ 2500 M1HT |

4" Flg |

1700 |

30 |

|

NFZ 2500 M01 |

NFZ 2500 M1HT |

4" Flg |

2100 |

38 |

|

NFZ 3500 M01 |

NFZ 3500 M1HT |

6" Flg |

2400 |

50 |

|

NFZ 4000 M01 |

NFZ 4000 M1HT |

6" Flg |

3100 |

60 |

|

NFZ 5000 M01 |

NFZ 5000 M1HT |

6" Flg |

3800 |

85 |

|

NFZ 5000 M01 |

NFZ 5000 M1HT |

6" Flg |

4300 |

85 |

|

NFZ 7500 M01 |

NFZ 7500 M1HT |

8" Flg |

5000 |

100 |

|

BPA 7750 |

NFZ 8500 M01 |

NFZ 8500 M1HT |

8" Flg |

6250 |

120 |

Specifications |

Standard |

Optional |

|---|---|---|

Maximum particle size (ISO class) |

class 2 (1 micron) |

class 1 (0.01 micron) |

Maximum water content (ISO class) |

class 2 (-40°F pdp) |

- |

Minimum / design / maximum operating pressure range |

80 psig / 100 psig / 150 psig | 58 to 250 psig |

Minimum / design / maximum ambient temperature |

38°F / 100°F/ 120°F | - |

Minimum / design / maximum inlet temperature |

38°F / 100°F/ 120°F | - |

Power supply requirements |

460 VAC / 60 Hz |

575V / 60 Hz or 380 VAC / 50 Hz |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.