Product Documentation

- Brochures

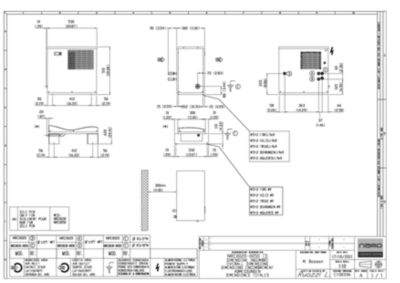

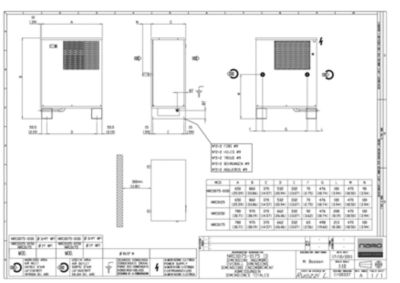

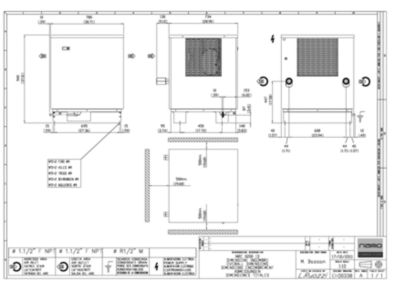

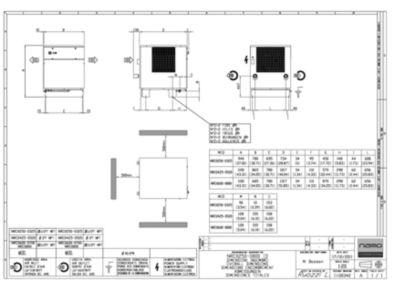

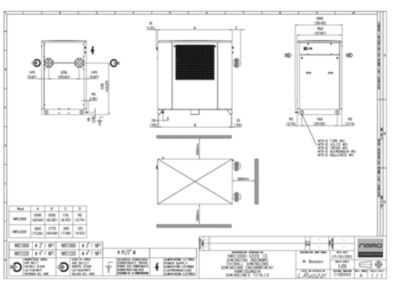

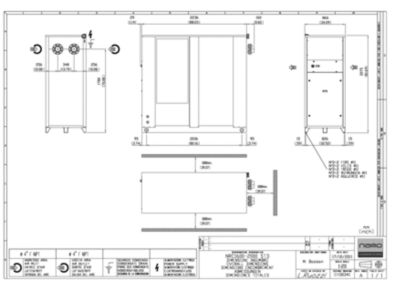

- GA Drawing

- Material Safety Data Sheets

- User Guides

Technical Data by Model

Dryer Model |

Inlet & Outet |

Rated Flow at 100 psig |

Absorbed Power |

Power Supply (V/Ph/60Hz) |

||||

|---|---|---|---|---|---|---|---|---|

NPT/Flg |

scfm |

kW |

115/1 |

230/1 |

230/3 |

460/3 |

575/3 |

|

NRC 0020 |

½” |

20 |

0.26 |

• |

||||

NRC 0030 |

½” |

30 |

0.26 |

• |

° |

|||

NRC 0050 |

½” |

50 |

0.36 |

• |

° |

|||

NRC 0075 |

½” |

75 |

0.50 |

• |

° |

|||

NRC 0100 |

¾” |

100 |

0.64 |

• |

• |

|||

NRC 0125 |

1” |

125 |

0.97 |

• |

• |

|||

NRC 0150 |

1” |

150 |

0.92 |

• |

• |

|||

NRC 0175 |

1” |

175 |

1.11 |

• |

• |

|||

NRC 0200 |

1 ½” |

200 |

1.30 |

• |

• |

• |

° |

|

NRC 0250 |

1 ½” |

250 |

1.32 |

• |

• |

• |

° |

|

NRC 0325 |

1 ½” |

325 |

2.07 |

• |

° |

• |

° |

|

NRC 0425 |

2” |

425 |

2.82 |

• |

• |

° |

||

NRC 0520 |

2” |

520 |

3.28 |

° |

• |

° |

||

NRC 0600 |

2 ½” |

600 |

3.49 |

° |

• |

° |

||

NRC 0700 |

2 ½” |

700 |

3.64 |

° |

• |

° |

||

NRC 0800 |

2 ½” |

800 |

4.28 |

° |

• |

° |

||

NRC 1000 |

3” Flg |

1000 |

5.09 |

° |

• |

° |

||

NRC 1220 |

4” Flg |

1220 |

6.48 |

° |

• |

° |

||

NRC 1600 |

4” Flg |

1600 |

8.55 |

° |

• |

° |

||

NRC 2000 |

4” Flg |

2000 |

10.75 |

° |

• |

° |

||

Specifications |

NRC 0020 to 0325 |

NRC 0425 to 1220 |

NRC 1600 to 2000 |

|---|---|---|---|

Design operating pressure range |

0 to 232 psig | 0 to 232 psig | 0 to 232 psig |

Design inlet air temperature range |

41 to 158°F | 41 to 158°F | 41 to 149°F |

Design ambient temperature range |

41 to 115°F | 41 to 115°F | 41 to 110°F |

Condenser cooling options |

air only |

air (standard) or water (optional) |

air (standard) or water (optional) |

Refrigerant type |

R134a |

R134a |

R134a |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.