Used throughout the entire production process, compressed air plays a vital role in the manufacture of paper and paperboard products. We’ve outlined the entire process to pinpoint exactly where compressed air is needed.

Where You'll Find Compressed Air Equipment

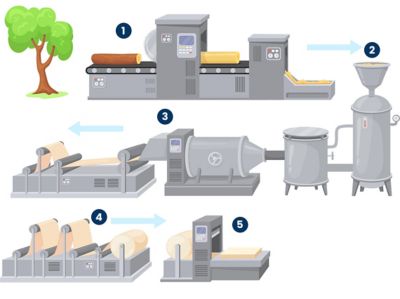

The paper industry typically consists of three basic input raw materials streams. The raw materials can be long logs, chips, or recycled wastepaper.

- The long log processes start with the debarking of incoming logs and feeding them to a chipper. The compressed air usage in this part of the process is typically pneumatic cylinders.

- Once the chips leave that area on conveyors they are transferred to the digesters where chemicals are added to break down wood, remove unwanted chemicals such as turpentine and lignin, and prepare those fibers to go to refining where they are broken down into a pulp. In this portion of the process, compressed air is used for pneumatic cylinders, valve actuation, and instrumentation.

- Fibers are then fed into the head box of the paper machine and distributed onto the wire/felt, usually 240 inches in width, where vacuum pumps extract the water as it goes through a series of press rolls. In this area compressed air is used for solar actuation on the roles to control pressure, on palm guides, a very critical item, to be sure that the wire is centered on the paper machine roll bed. After the sheet is pressed it goes to the dryer section where it is fed through a series of steam-heated dryer cans, pressed even more thinly, and the water removed to the specified dryness. In this area, compressed air is used for pneumatic cylinder actuation and instrumentation, and very often to keep the lenses of the TV cameras that are used to monitor the process free of fibers and steam contamination.

- Once the sheet passes through the dryer section it goes to the roll takeoff area where it is rolled in one large role sometimes weighing as much as 20 tons and removed from the paper machine to the Winder/slitter area. Once again in this area, the primary use of compressed air is pneumatic cylinder actuation as well as process control instrumentation.

- On the Winder slitter, the 240" wide roll is wound in the opposite direction as a series of circular knives cut it into specified widths as required by the paper mill customer. In this area compressed air usage is pneumatic cylinders, instrumentation, and TV cameras.

Compressed Air Products in Unexpected Places

Outside of the paper process involving the paper machine, compressed air is utilized in the power and utilities area for boiler instrumentation, soot blowing, valve actuation, and again TV cameras.

As part of the paper-making process, the areas of the mill are chemical preparation and supply. These differ between a Kraft mill, a bleach paper mill, and a cellulose fiber mill.

The commonality of the use of compressed air is primarily instrumentation and valve actuation. There are also usually several double diaphragm air-actuated pumps used for chemicals that are not suitable for conventional centrifugal pumps.

Pulp & Paper Material Management

Many paper mills have a kiln area as part of the input stream to the chemical area. In the kiln area compressed air is used for cylinder actuation, TV cameras, instrumentation, valve actuation, and double diaphragm air pumps.

Paper mills that use chips as a raw manufacturing materials stream do so without the need for debarking and chipping, but the balance of the process remains the same.

Those mills utilizing wastepaper do so without the debarking and chipping process. They do have material handling conveyors and hydro pulpers which use compressed air for cylinder actuation, TV cameras, instrumentation, and valves.

Paper Industry Innovation

Throughout the industry, compressed air is utilized when there is a sheet break to blow scrap paper out of the rolls across the floor into a pit where is recovered for recycling.

With the numerous uses of compressed air throughout a pulp and paper mill, a traditional twin-tower desiccant air dryer is the top choice with the ability to withstand harsh mill conditions and produce the vast amount of clean, dry compressed air required.