Why is Oil in My Compressed Air Equipment?

Oil is consistently used across all compressed air equipment lines as lubricant for all the inner moving parts. Without the oil layer, many of the mechanical components don’t run smoothly and run the risk of damage. But oil in the wrong parts of your system can wreak havoc on your production.

Oil water separators rely on multiple filtration layers to separate particles from the expelled liquid from your compressed air system. Why pay someone to dispose of your industrial wastewater when you can filter your own condensate for safe removal down your own drains?

Article Topics:

How Oil Water Separators Work

Benefits of On-Site Separation

Oil Vapor Removal Systems

Oil Water Separators

A successful compressed air and gas treatment system includes equipment that removes condensate from the process. Although it looks like plain water, there may be traces of oil in the drainage. This means you would need to dispose of the product properly. But what if there was a way to clean the extracted material so you can dispose of it safely down your drain?

Products like nano-purification’s Sepura products remove the oil from the water in your condensate so you can dispose of it cleanly and safely, drastically reducing your condensate disposal costs.

Sepura uses advanced design and unique environmentally friendly STERLING oil absorbing filtration media. This product has no messy carbon bags, settling tanks full of untreated condensate., or external oil collection containers.

Key Features:

lower outlet concentrations - down to 5 ppmv or less

environmentally friendly recycled materials

treatment for systems up to 10,000 scfm with a single unit

How These Products Work

Piping guides any water build-up out from the condensate drain and into the Sepura separator. Waste water filters through a filler which reduces the pressure of the condensate and removes and leftover particles.

The condensate continues into the next layer of filtration, which removes any oil particles that may be leftover in the condensate. The water separates into it’s own disposable container for safe and easy discard down any normal sink drain.

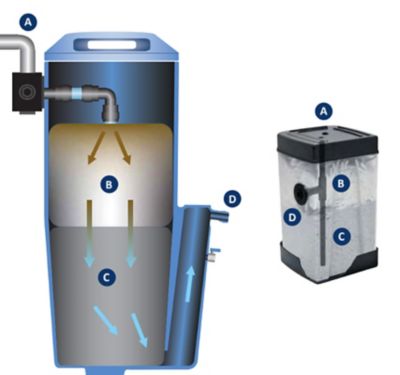

A - Condensate from compressors, refrigerated dryers, coolers, filters or any other drain points are piped directly to the SepuraTM oil water separator

B - Condensate passes through the primary filter which depressurizes the condensate, traps solid particles protecting the secondary filter and catches bulk hydrocarbons within a high capacity oil absorbent

C - Condensate passes through a deep bed of STERLING filtration media which absorbs the oil providing outlet oil concentrations down to 5 ppmv or less

D - Remaining water can be disposed of safely and in compliance with environmental regulations

Benefits of On-Site Separation

Handling oil water separation on your own premises not only saves you money, but is also better for the environment. The filter material in our Sepura oil water separator is made from 100% recycled materials and no oil collects at the bottom of the container.

Instead of waiting for a company to safely dispose of your contaminated wastewater, you can find the best product for your specific flow rate anywhere between 60 to 7000 scfm. Models SEP ST 120 through SEP 2500 ST also come standard with a 10-year warranty, which means less products to replace.

Oil Vapor Removal Systems

These products reduce oil vapor and odor from any compressed air system using activated carbon towers. Since these oil droplets are considered a harmful waste product, various industries must make sure they do not dump any of it down their regular sewage drains.

Key Features:

Reduces residual oil content to lower than 0.003 mg/m3 @ 95°F and 100 psig inlet pressure

unit delivers air quality to ISO 8573-1 (class 1 for oil)

6 models with rated flows from 40 to 1500 scfm

Conclusion

We want to make sure your compressed air equipment lasts you for years to come, and maintenance and monitoring goes a long way. As long as you have a nano product, you won't be disappointed.

Contact our team to get the best tips and tricks for keeping your compressed air system clean and dry.