R134a or R407C refrigerant and non-toxic silica dry mass utilized in all models.

Key Specs:

Flow Rate

20 to 2000 scfm

Connection

½” NPT to 4” Flg

Product Grade

ISO 8573.1:2010 Class 4 - 6

Product Documentation

- Brochures

- User Guides

- Worksheets

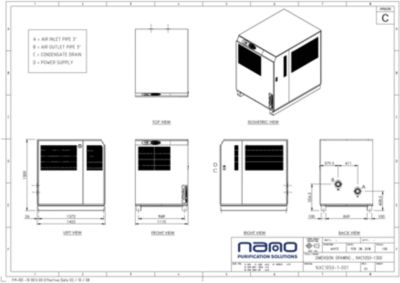

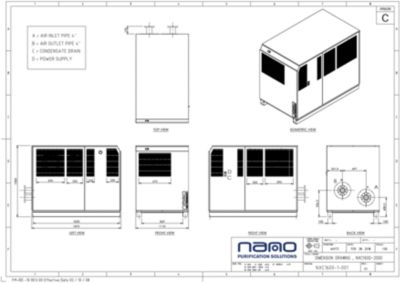

- General Arrangement Drawings

- Material Safety Data Sheets

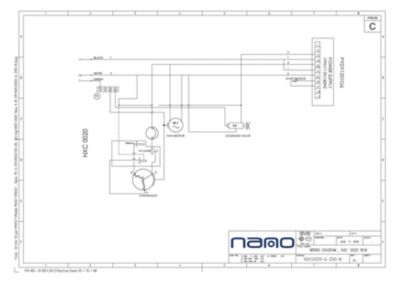

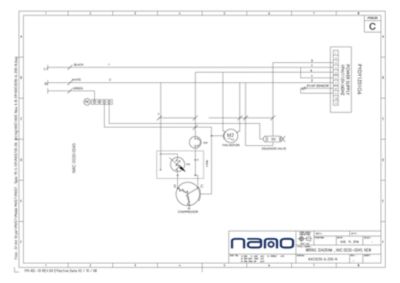

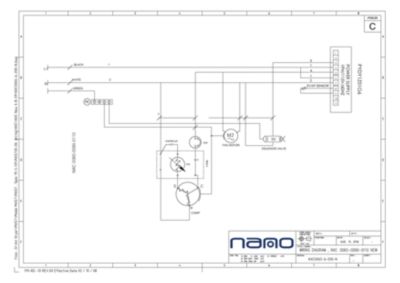

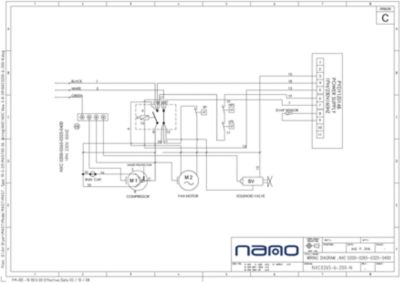

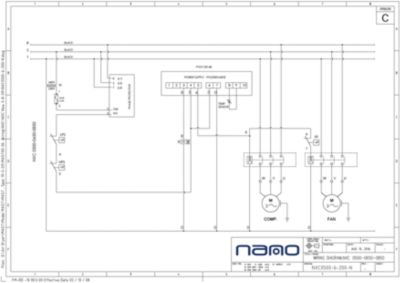

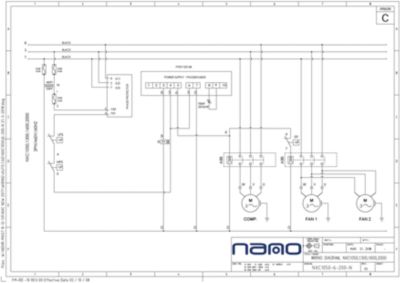

- Electrical Diagrams

Features

Easy to install, and start up with no overnight precooling of thermal mass required.

Pre- and after filter packages available to provide additional energy savings and improved air quality.

Specifications of Our Models

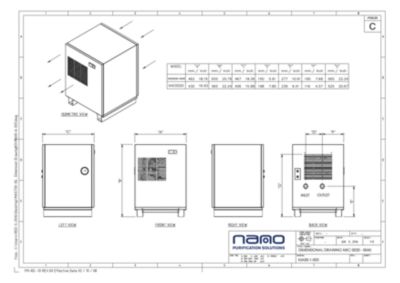

Cycling Refrigerated Air Dryer Model |

Recommended |

Inlet & Outlet |

Rated Flow |

Absorbed Power |

Power Supply (V/Ph/60Hz) |

|||

|---|---|---|---|---|---|---|---|---|

Prefilter |

After Filter |

NPT/Flg |

scfm |

kW |

115/1 |

230/1 |

460/3 |

|

GFN 0050 M1 |

GFN 0050 M01 |

½" |

20 |

0.23 |

• |

|||

GFN 0085 M1 |

GFN 0085 M01 |

¾" |

30 |

0.24 |

• |

|||

GFN 0105 M1 |

GFN 0085 M01 |

¾" |

45 |

0.25 |

• |

|||

GFN 0105 M1 |

GFN 0105 M01 |

1" |

65 |

0.47 |

• |

|||

GFN 0105 M1 |

GFN 0105 M01 |

1" |

90 |

0.49 |

• |

|||

GFN 0125 M1 |

GFN 0125 M01 |

1" |

110 |

0.51 |

• |

|||

GFN 0325 M1 |

GFN 0325 M01 |

1 ½" |

130 |

0.97 |

• |

|||

GFN 0325 M1 |

GFN 0325 M01 |

1 ½" |

165 |

1.02 |

• |

|||

(Models NXC 0020 to NXC 0165: UL STD 60335-1 & 60335-2-40 / CSA STD C22.2) |

||||||||

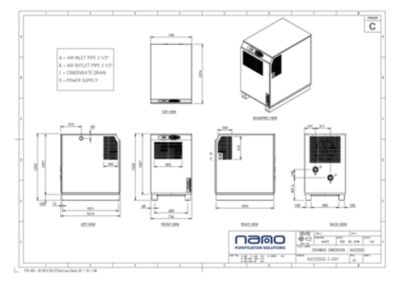

GFN 0450 M1 |

GFN 0450 M01 |

2" |

200 |

1.41 |

• |

|

||

GFN 0450 M1 |

GFN 0450 M01 |

2" |

200 |

1.41 | • | |||

GFN 0450 M1 |

GFN 0450 M01 |

2" |

265 |

1.41 |

• |

|

||

GFN 0450 M1 |

GFN 0450 M01 |

2" |

265 |

1.41 | • | |||

GFN 0450 M1 |

GFN 0450 M01 |

2" |

325 |

1.47 | • | |||

GFN 0450 M1 |

GFN 0450 M01 |

2" |

325 |

1.47 |

|

• |

||

GFN 0450 M1 |

GFN 0450 M01 |

2" |

400 |

1.52 | • | |||

| NXC 0400 | GFN 0450 M1 |

GFN 0450 M01 |

2" | 400 | 1.52 | • | ||

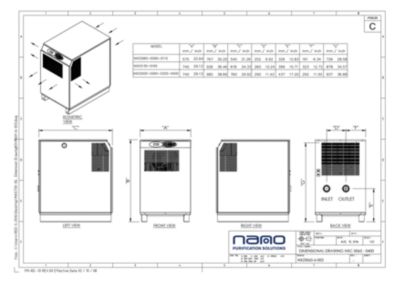

GFN 0850 M1 |

GFN 0850 M01 |

2 ½" |

500 |

2.50 |

• |

|||

GFN 0900 M1 |

GFN 0900 M01 |

3" |

650 |

3.46 |

• |

|||

GFN 0900 M1 |

GFN 0900 M01 |

3" |

850 |

3.60 |

• |

|||

GFN 01250 M1 |

GFN 1250 M01 |

3" |

1050 |

5.00 |

• |

|||

GFN 1500 M1 |

GFN 1500 M01 |

3" |

1300 |

5.15 |

• |

|||

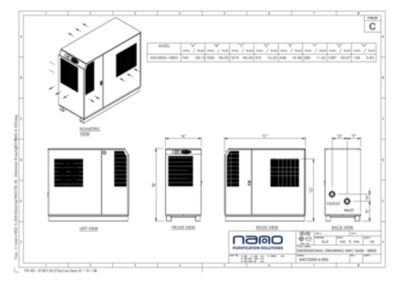

NFZ 2500 M1 |

NFZ 2500 M01 |

4" Flg |

1600 |

6.90 |

• |

|||

NFZ 2500 M1 |

NFZ 2500 M01 |

4" Flg |

2000 |

7.20 |

• |

|||

Specifications |

|

|---|---|

Design operating pressure range |

0 to 232 psig |

Maximum inlet temperature |

158°F |

Maximum ambient temperature |

110°F - 122°F depending on refrigerant (contact support for details) |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.