In numerous systems, multiple stages of filtration are essential for effectively eliminating various types of contaminants. Typically, a particulate filter operates first to capture large particles, followed by a coalescing filter that handles oil and water separation. The number of stages is determined by the required air quality and the specific contaminants involved.

Key specs:

Flow Rate

6 to 1500 scfm

Connection

⅛” to 3” NPT (F)

Filtration

1 & 0.01 micron & activated carbon

Product Documentation

- Brochures

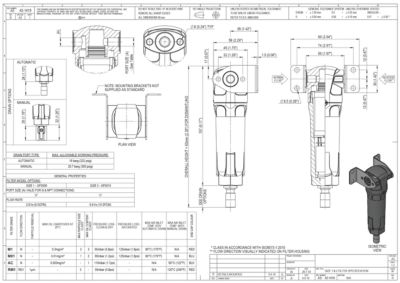

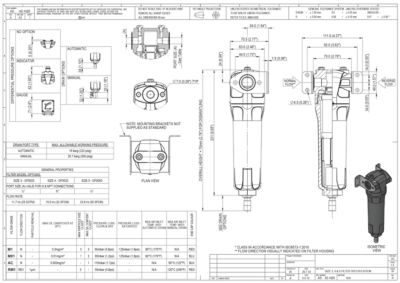

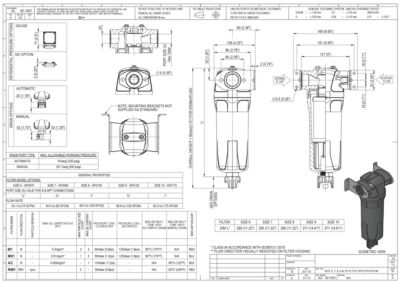

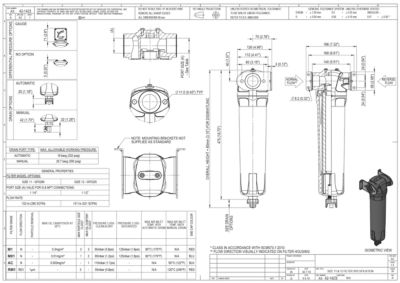

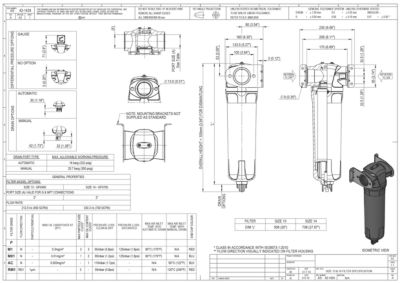

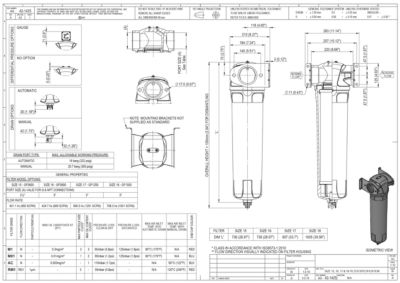

- General Arrangement Drawings

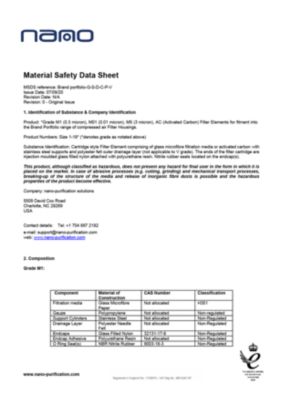

- Material Safety Data Sheets

- Spare Parts Guide

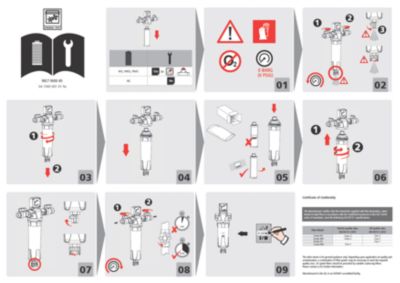

- User Guides

Features

Die cast aluminum housing with internal and external E-Coat™ finishing for optimum corrosion resistance.

No-tie rod allows for easy bowl removal and maintenance.

Specifications of Our Models

Compressed Air & Gas Filter Model |

Replacement Element | Inlet & Outlet | Rated Flow at 100 psig |

|---|---|---|---|

| Part No. | NPT | scfm | |

| GFN 0006 (grade) | GE 0015 (grade) | ⅛” | 6 |

| GFN 0015 (grade) | GE 0015 (grade) | ¼” | 15 |

| GFN 0025 (grade) | GE 0032 (grade) | ¼” | 25 |

| GFN 0032 (grade) | GE 0032 (grade) | ⅜” | 32 |

| GFN 0050 (grade) | GE 0050 (grade) | ½” | 50 |

| GFN 0070 (grade) | GE 0105 (grade) | ½” | 70 |

| GFN 0085 (grade) | GE 0105 (grade) | ¾” | 85 |

| GFN 0105 (grade) | GE 0105 (grade) | 1” | 105 |

| GFN 0125 (grade) | GE 0175 (grade) | ¾” | 125 |

| GFN 0175 (grade) | GE 0175 (grade) | 1” | 175 |

| GFN 0280 (grade) | GE 0325 (grade) | 1 ¼” | 280 |

| GFN 0325 (grade) | GE 0325 (grade) | 1 ½” | 325 |

| GFN 0450 (grade) | GE 0450 (grade) | 2” | 450 |

| GFN 0700 (grade) | GE 0700 (grade) | 2” | 700 |

| GFN 0850 (grade) | GE 0900 (grade) | 2 ½” | 850 |

| GFN 0900 (grade) | GE 0900 (grade) | 3” | 900 |

| GFN 1250 (grade) | GE 1250 (grade) | 3” | 1250 |

| GFN 1500 (grade) | GE 1500 (grade) | 3” | 1500 |

Specifications |

GFN 0006 to GFN 0015 |

GFN 0025 to GFN 0050 |

GFN 0070 to GFN 1500 |

|---|---|---|---|

Design operating pressure range |

0 to 232 psig |

0 to 232 psig |

22 to 232 psig |

Automatic float drain |

GFDK 0050 | GFDK 0050 |

GFDK 1500 |

Differential pressure gauge |

- | - |

GFDP 1500 |

Differential pressure indicator |

- | GFDP 0050 |

- |

Element Performance |

M1 |

M01 |

AC |

|---|---|---|---|

Maximum particle size (ISO Class) |

3 |

1 |

- |

Maximum oil content (ISO Class) |

3 |

2 |

1 |

Particle removal |

1 micron |

0.01 micron |

- |

Max oil carryover at 68°F |

0.3 ppm |

0.01 ppm |

0.003 ppm |

Design operating temperature range |

32 to 176°F |

32 to 176°F |

32 to 122°F |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.

Frequently Asked Questions

A compressed air and gas filter is a crucial device expertly designed to eliminate contaminants such as dust, moisture, oil, and particles from compressed air or gas systems. These filters guarantee that the air or gas remains impeccably clean and dry, safeguarding machinery, tools, and equipment from damage and enhancing the quality of the output. This is especially vital in sensitive applications such as medical, food, or industrial processes. Without effective filtration, impurities can significantly diminish efficiency, lead to equipment failure, or compromise product quality. Thus, using a filter is essential for ensuring optimal system performance and longevity.

- Particulate Filters: Remove solid particles like dust and dirt.

- Coalescing Filters: Separate water and oil aerosols from the air or gas.

- Activated Carbon Filters: Remove odors and trace gases by adsorption.

nano GFN compressed air and gas filters expertly utilize a powerful combination of mechanical filtration, coalescing, and adsorption to eliminate contaminants effectively. As compressed air or gas flows through the filter, particles are efficiently trapped within a deep-pleated filter medium or coalescer, while water and oil are skillfully separated and expelled.

- M1: Primary filtration for particulate and oil removal

- M01: To be used after an M1 filter, the M01 grade provides finer particulate and oil removal

- AC: To be used after an M1/M01 filter, the AC grade removes odors and oil vapors

Filter size is based on the flow rate and pressure requirements of your compressed air or gas system. It’s essential to match the filter size to the specific needs of your system to ensure optimal filtration and prevent restrictions or performance loss. You should select a filter that matches or exceeds the flow rate of your system to maintain optimal performance. The flow rate is critical to ensure that the filter can handle the volume of compressed air or gas your system requires without causing excessive pressure loss or inefficiency. The GFN range includes filters with flow rates ranging from 6 to 1500 scfm to accommodate all small to mid-flow applications. Our high-capacity fabricated filter range is the solution for more significant flows of up to 10,000 scfm.

The maximum pressure rating for our GFN range is 232 psig. It's essential to match the filter's pressure rating with the pressure level of your compressed air or gas system. Using a filter with an insufficient pressure rating can lead to damage or failure, so ensuring compatibility is essential. We offer a mid-pressure filter range rated at 750 psig for applications requiring higher-pressure solutions. For even higher pressures, our high-pressure stainless-steel filters are designed to handle up to 5000 psig.

Grade M1 and M01 filters can withstand a maximum design temperature of 176°F, whereas the AC grade has a maximum of 122°F. Filters have a specific temperature range they can operate within. Make sure to choose a filter that can withstand the temperature of your compressed air or gas system to avoid damage or malfunction. If you are dealing with a high-temperature application, our GFHTN high-temperature range is the perfect solution for your needs, able to handle temperatures up to 450°F.

Certain filters are made specifically for particular gases, such as nitrogen, oxygen, or hydrogen. It is important to ensure that the filter you buy is compatible with the type of gas used in your system. Using an incorrect filter may result in ineffective filtration or even cause system failure. For the best recommendations on filters based on the specific gas you need to filter, consult a nano specialist.

The GFN range has been tested in accordance with ISO 12500-4. Our filters are also performance validated by a third party.

nano GFN filter housings are made from die-cast aluminum and feature a durable powder-coated exterior. They also have an internal and external E-Coat™ finish for superior corrosion resistance. The filter element is constructed from borosilicate microfiber, and the end caps are glass-filled nylon.

Grade M1 and M01 filters are equipped with a reliable automatic float drain, while our grade AC filters come with a robust manual drain.

External condensate drains are readily available, including options like timed solenoid drains and zero air loss drains.

A filter's lifespan depends on the type of contaminants in your system, the quality of the filter, and maintenance practices. Regular monitoring and maintenance are essential to ensure continued efficiency.

Filters must undergo regular maintenance to ensure optimal performance. This critical process includes checking the pressure drop across the filter, draining water from coalescing filters, and replacing filter elements as needed. The maintenance frequency will vary based on your system's usage and environmental conditions, but staying proactive in these tasks is essential for efficiency and longevity. You can easily find the service intervals for GFN filter components in our spare parts guide. If you need further details, our nano technical support team is ready to assist you.

Grade M1 and MO filter elements must be replaced annually. In addition, the Grade AC filter element must be replaced after every 1,000 hours of operation. For detailed information on replacement elements, refer to our spare parts guide.

nano offers high-quality wall mounting and connecting kits designed for optimal performance. Our wall mounting kits ensure a secure attachment of filters to any wall, maximizing your available space. Meanwhile, the connecting kits make it effortless to install multiple filter applications, streamlining your setup with ease and efficiency. For comprehensive information on the accessories available for the GFN range, be sure to check out our spare parts guide.

The cost is determined by the size required for your compressed air system.

nano GFN housing: 10 years from the date of shipment. All other components: 18 months from the date of shipment (from the factory) or 12 months from the date of installation/start-up, whichever occurs first • Coverage: 100% parts only

If your system has specific requirements or operates under unique conditions, a custom filter solution is essential. Don't hesitate to contact the nano team for a specialized solution tailored specifically to your application.