Die-cast aluminium housing with internal and external E-Coat™ finishing for optimum corrosion resistance.

Key Specs:

Flow Rate

10 to 2550 Nm3/h

Connection

⅛” to 3” BSPP

Added Feature

Automatic Drain

Product Documentation

- Brochures

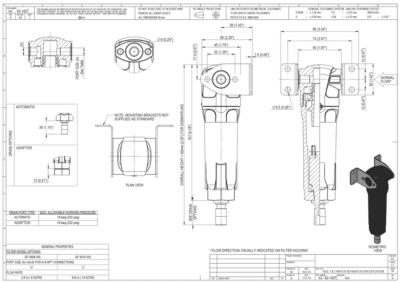

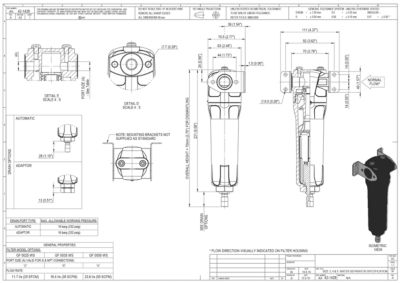

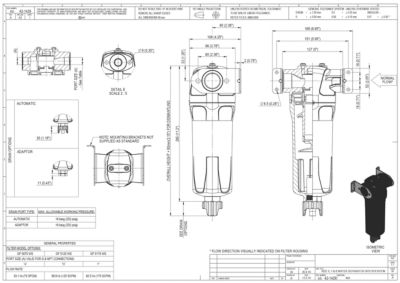

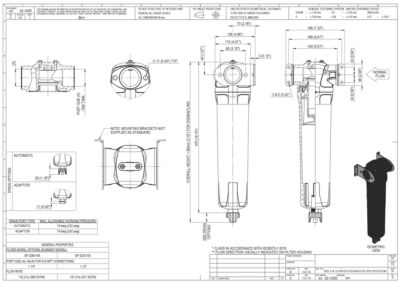

- General Arrangement Drawings

- Spare Parts Guide

Features

Ensures the separated liquids cannot re-enter the air or gas stream greatly improves drainage and further improves separation performance.

This range works with a broader spectrum of flow rates.

Specifications of Our Models

Water Separator Model |

Inlet & Outlet |

Rated Flow |

|---|---|---|

BSPP |

Nm3/h |

|

GFNB 0006 WS |

⅛” |

10 |

GFNB 0015 WS |

¼” |

25 |

GFNB 0025 WS |

¼” |

42 |

GFNB 0035 WS |

⅜” |

60 |

GFNB 0050 WS |

½” |

85 |

GFNB 0070 WS |

½” |

119 |

GFNB 0125 WS |

¾” |

213 |

GFNB 0175 WS |

1” |

298 |

GFNB 0280 WS |

1 ¼” |

476 |

GFNB 0325 WS |

1 ½” |

553 |

GFNB 0700 WS |

2” |

1190 |

GFNB 0850 WS |

2 ½” |

1445 |

GFNB 1500 WS |

3” |

2550 |

Specifications |

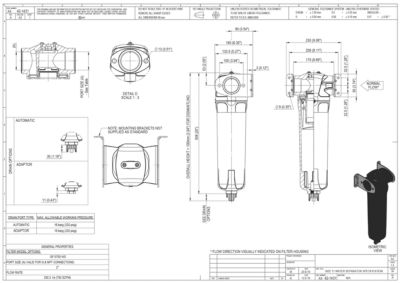

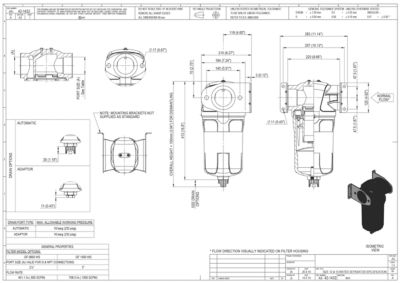

GFNB 0006 to 0050 WS |

GFNB 0070 to 1500 WS |

|---|---|---|

Recommended operating temperature range |

1.5 to 80°C |

1.5 to 80°C |

Design operating temperature range |

1.5 to 80°C |

1.5 to 80°C |

Design operating pressure range |

1.5 to 16 barg |

1.5 to 16 barg |

Condensate drain (included) |

GFDK 0050 |

GFDK 1500 |

Frequently Asked Questions

A water separator removes bulk water from the compressed air system to prevent corrosion, contamination, and damage to pneumatic tools, machinery, and equipment. Water in the compressed air can cause irregularities in the operation of pneumatic equipment, such as inconsistent performance or freezing in cold environments. Removing the moisture ensures the compressed air remains dry and maintains consistent, efficient air tools and machinery performance. It’s essential for maintaining the efficiency and longevity of your air-powered systems.

nano’s mechanical water separators use centrifugal force to capture and remove water from compressed air before it enters the equipment or tools. The force spins the compressed air, causing the water to separate and collect at the bottom, where it can be drained.

If your system has multiple compressors or airlines, installing a water separator at each point where moisture could accumulate is usually a good idea. This will help prevent moisture from traveling through the entire system and damaging equipment downstream.

Regular maintenance includes checking the drain valve and ensuring the water separator is free of blockages. It's important to follow nano’s maintenance schedule to keep the unit in optimal working condition.

Models GFNB 0006 WS to GFNB 1500 WS are supplied with an automatic float drain as standard. The automatic drain expels water when it reaches a certain level, saving you time and effort by reducing the need for manual intervention. Unlike traditional manual drains, which require emptying the collected water, our automatic system ensures continuous operation with minimal maintenance, allowing you to focus on more critical tasks. Overall, the automatic float drain enhances efficiency, reliability, and ease of use, making it the better choice for managing water separation with minimal hassle.

Yes, external timer drain and zero air loss condensate drain options are available.

While a water separator removes bulk water from a compressed air system, it does not remove all types of contaminants, such as oil or dust. nano GFNB oil coalescing or particulate filters are required to remove these contaminants.

Yes, nano water separators have been tested in accordance with ISO 12500-4.

Wall mounting kits are available from nano. These kits allow you to securely mount the water separator to a wall for space optimisation.

The cost varies depending on the water separator size required for your compressed air system.

nano GFNB WS water separator housing: 10 years from the date of shipment. All other components: 18 months from the date of shipment (from the factory) or 12 months from the date of installation/start-up, whichever occurs first • Coverage: 100% parts only