The all-in-one package includes an integral oxygen analyser that continuously monitors the supplied gas purity. It also includes a soft start valve that protects the membranes and extends their life and an inlet filtration system that ensures the membranes are protected against contamination. All of these components are housed in a stainless steel cabinet.

Key Specs:

Purity

99.3 to 95%

Flow Rate

0.3 to 228.9 Nm3/h

Added Feature

Purity and Flow Adjustment

Product Documentation

- Brochures

- Certificates

- General Arrangement Drawings

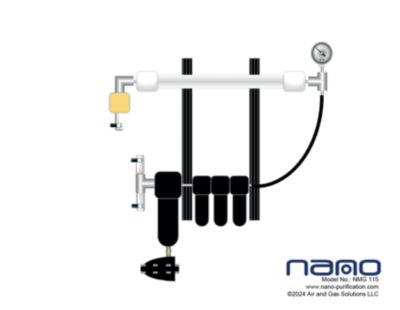

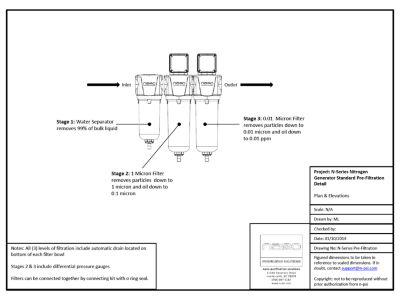

- Pre Filtration Diagram

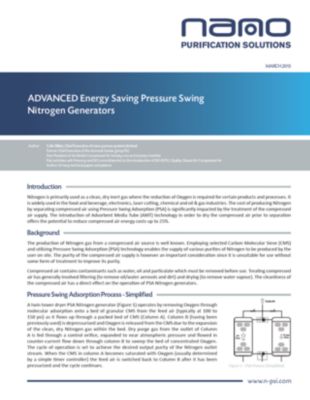

- Technical Paper

- User Guides

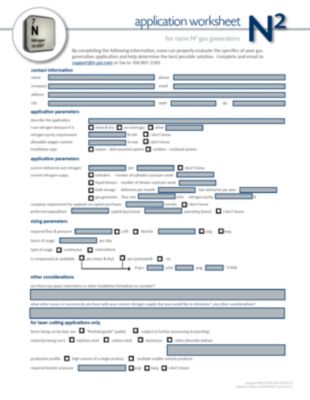

- Worksheet

Features

Typical ROI in under 24 months with savings over high-pressure cylinders or liquid gas supplies and low energy consumption.

The cabinet design, complete with casters, is compact and requires no start-up time or buffer vessels.

Specifications of Our Models

Generator Model |

Rated Outlet Flow at 7 barg |

Nitrogen purity at the outlet (Max. oxygen content) |

||||||

|---|---|---|---|---|---|---|---|---|

99.3% (30%) |

99.5% (50%) |

99% (1%) |

98% (2%) |

97% (3%) |

96% (4%) |

95% (5%) |

||

NMG 2L1 |

Nm3/h |

0.3 |

0.4 |

0.5 |

0.8 |

1 |

1.2 |

1.5 |

NMG 2L2 |

Nm3/h |

0.6 |

0.8 |

1 |

1.6 |

2 |

2.4 |

3 |

NMG 2L3 |

Nm3/h |

0.9 |

1.2 |

1.5 |

2.4 |

3 |

3.6 |

4.5 |

NMG 2L4 |

Nm3/h |

1.2 |

1.6 |

2 |

3.2 |

4 |

4.8 |

6 |

NMG 4S1 |

Nm3/h |

2.5 |

2.9 |

4.4 |

6.4 |

8.2 |

10 |

12 |

NMG 4L1 |

Nm3/h |

5.2 |

5.9 |

8.9 |

12.8 |

16.4 |

20.1 |

24 |

NMG 4L2 |

Nm3/h |

10.4 |

11.8 |

17.8 |

25.6 |

32.8 |

40.2 |

48 |

NMG 6S1 |

Nm3/h |

11 |

12.5 |

19.5 |

27.9 |

36.1 |

44.1 |

52.8 |

NMG 6L1 |

Nm3/h |

15.9 |

18.1 |

28.1 |

40.4 |

52.2 |

63.8 |

76.3 |

NMG 6S2 |

Nm3/h |

22 |

25 |

39 |

55.8 |

72.2 |

88.2 |

105.6 |

NMG 6L2 |

Nm3/h |

31.8 |

36.2 |

56.2 |

80.8 |

104.4 |

127.6 |

152.6 |

NMG 6L3 |

Nm3/h |

47.7 |

54.3 |

84.3 |

121.2 |

156.6 |

191.4 |

228.9 |

Air Factor |

Nm3/h |

6.2 |

5.0 |

4.0 |

3.2 |

2.7 |

2.4 |

2.2 |

Specifications |

|

|---|---|

Design operating pressure range |

6 to 16 barg |

Design operating temperature range |

5 to 50°C |

Recommended inlet air temperature |

10 to 45°C |

Inlet air quality |

ISO 8573.1 class 1, 4, 1 |

Supply voltage |

110-240 VAC, 50/60Hz |

Rower rating |

4 W |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.