These models provide a typical return on investment between 6 to 24 months.

Key Specs:

Purity

95 to 99.999%

Flow Rate

0.3 to 18.8 Nm3/h

Pressure RATING

6 to 10 barg

Product Documentation

- Brochures

- Certificates

- Electrical Diagrams

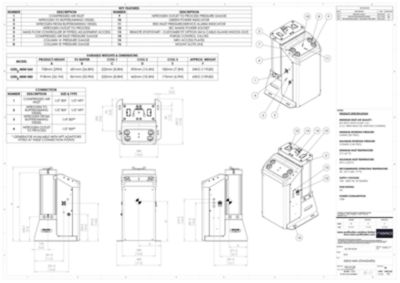

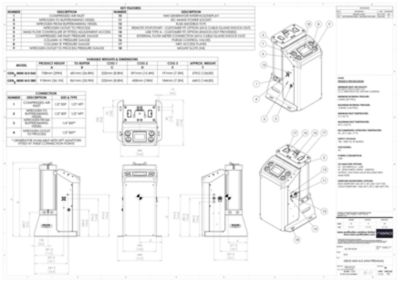

- General Arrangement Drawings

- Material Safety Data Sheets

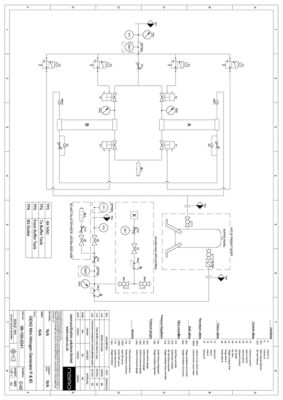

- P & ID

- User Guides

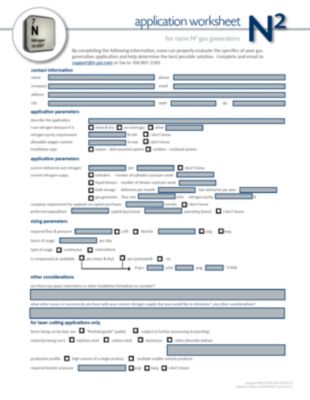

- Worksheet

Features

Plug-and-play system can be installed easily with minimum cost and interruption.

Compact design allows installation in spaces too small for twin tower generator systems.

Specifications of Our Models

| Model | Rated Outlet Flow at 7 barg |

Nitrogen Purity at the Outlet (Maximum Oxygen Content) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 ppm | 50 ppm | 100 ppm | 500 ppm | 1000 ppm | 0.5% | 1% | 2% | 3% | 4% | 5% | ||

| GEN2MINI-060 | Nm3/h | - | - | - | 0.6 | 0.8 | 1.7 | 2.1 | 2.8 | 3.4 | 3.9 | 4.3 |

| GEN2MINI-080 | Nm3/h | 0.3 | 0.8 | 1.0 | 1.3 | 1.7 | 2.8 | 3.7 | 4.7 | 5.5 | 6.3 | 6.9 |

| GEN2MINI-100 | Nm3/h | 0.5 | 1.3 | 1.5 | 2.2 | 2.5 | 4.2 | 5.3 | 6.9 | 7.8 | 8.7 | 9.6 |

| GEN2MINI-110 | Nm3/h | 0.8 | 1.4 | 1.7 | 2.7 | 3.2 | 5.2 | 6.4 | 7.8 | 8.8 | 10.1 | 11.1 |

| GEN2MINI-120 | Nm3/h | 1.6 | 2.2 | 2.5 | 3.7 | 4.3 | 6.2 | 8.0 | 10.1 | 11.7 | 13.0 | 14.3 |

| GEN2MINI-130 | Nm3/h | 1.8 | 3.0 | 3.4 | 4.7 | 5.5 | 7.9 | 9.9 | 12.2 | 14.1 | 17.2 | 18.8 |

Specifications |

|

|---|---|

Recommended inlet air quality (ISO class) |

2.2.1 |

Minimum inlet air quality (ISO class) |

2.4.1 |

Minimum operating pressure |

6 barg |

Maximum operating pressure |

10 barg |

Recommended operating temperature range |

20 to 25ºC |

Minimum/maximum operating temperature range |

5 to 50ºC |

| Supply voltage | 100 - 240 V AC |

| Fuse rating | 3A 'T' |

| Frequency | 50 - 60 Hz |

| Maximum power consumption | 72 W |

| IP rating | IP53 (NEMA 2) |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.

Frequently Asked Questions

A nitrogen generator is a device that produces nitrogen gas (N₂) from compressed air. It uses separation methods, such as Pressure Swing Adsorption (PSA) and Membrane Technology, to remove oxygen and other gases, leaving purified nitrogen gas.

- Cost savings: Long-term savings are achieved by eliminating the recurring costs of purchasing bottled nitrogen.

- Convenience: Continuous on-site nitrogen generation eliminates the need for deliveries and reduces the risk of running out of nitrogen.

- Customisation: On-demand nitrogen generation allows you to tailor the flow and purity to your needs.

- PSA (Pressure Swing Adsorption): Uses carbon molecular sieves to separate nitrogen from other gases in compressed air under varying pressure.

- Membrane Technology: This technology uses selective permeable membranes to separate nitrogen from oxygen based on the size of the molecules.

The GEN2 MINI uses PSA or Pressure Swing Adsorption technology to separate nitrogen from other gases in compressed air.

GEN2 MINI nitrogen generators can produce nitrogen gas at purities between 95% to 99.999% purity. Achievable purity levels for nitrogen generators are relative to Oxygen content.

The necessary purity will vary based on your application. Different industries and uses (e.g., food packaging, pharmaceuticals, electronics, or industrial processes) will require various nitrogen purities. Our team will collaborate with you to understand your requirements.

The flow rate (measured in normal meter cube per hour, Nm³/h) will depend on the application. Understanding your nitrogen consumption is key to selecting the right system.

The cost of a GEN2 MINI nitrogen generator varies depending on its size, purity, and flow rate, as well as the inlet compressed air pre-treatment filtration and drying equipment.

Maintenance will involve regular filter changes, periodic system pressure checks, and monitoring the air compressor's performance. nano GEN2 MINI nitrogen generators have built-in diagnostics to assist with preventive maintenance. Regular servicing by the manufacturer or a qualified technician is crucial. Consult the GEN2 MINI service manual or contact our nano technical support team for more information.

The total energy usage varies based on the nitrogen generator size and flow rate. Most of the energy consumption is centered around the required inlet compressed air. For energy consumption for a specific model, view the technical data sheets found by model number in the specification table above.

The size and space required will depend on the nitrogen generator's capacity and model. The nano GEN2 MINI nitrogen generators' modular design makes them compact and easy to fit through a standard doorway. They are typically installed in industrial settings, where they can connect easily to compressed air sources and distribution systems. It’s important to ensure proper ventilation and adequate space for the unit. Always consult a certified nano distributor or a nano team member for assistance.

Various industries, such as food packaging, pharmaceuticals, and electronics, have specific requirements for nitrogen purity and flow rate. It's important to ensure that the nitrogen generator you choose meets your application's demands. Our expert team is here to guide you through the selection process, helping you choose the right model specifications for your unique needs. Contact us today to discuss your requirements.

Period: 30 months from date of shipment from the factory or 24 months from date of installation/start up, whichever occurs first • Coverage: 100% parts and labor per defined service time allowances • Requirements: Pre Filter & non-corrosive upstream piping required and completed start-up checklist required

While nitrogen is non-toxic, it is an asphyxiant in high concentrations. Proper ventilation is critical to prevent nitrogen buildup in enclosed spaces. Regularly monitoring nitrogen levels and following all safety guidelines is essential to avoid risks. Refer to the nano GEN2 MINI nitrogen generator user guide for detailed guidelines.

Yes, nitrogen generators can often be integrated with various types of machinery and production lines. Ensure your chosen system is compatible with your existing equipment, especially in automated or controlled environments.

The ROI will depend on your current nitrogen consumption and the cost of purchasing bottled nitrogen. Typically, a GEN2 MINI nitrogen generator can pay for itself in less than 24 months due to the savings on ongoing gas purchases, delivery fees, and surcharges.

Yes, our nitrogen generators can help reduce the carbon footprint by eliminating the need for frequent delivery trucks, packaging, and other logistics associated with bottled nitrogen. Additionally, they offer a more energy-efficient option than some other methods of nitrogen production.