We’ve constructed our X-CC fin and tube designs to be up to 60% smaller than other conventional components on the market

Key Specs:

Flow Rate

100 to 3500 scfm

Operating Temperatures

35 to 250°F

Max Allowable Working Pressure

250 psig

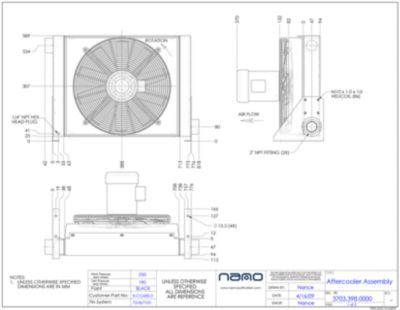

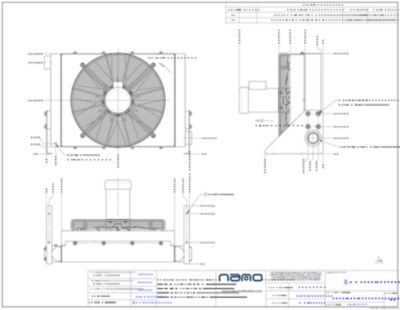

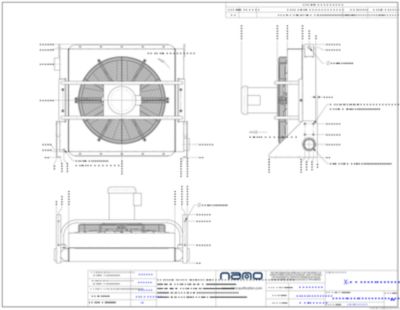

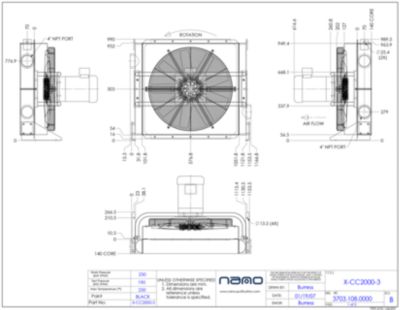

Product Documentation

- Brochures

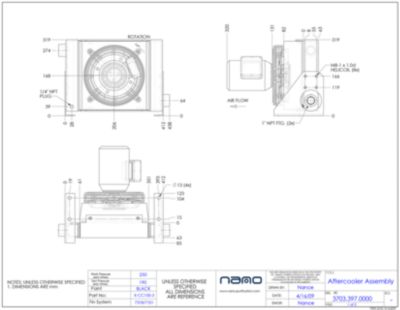

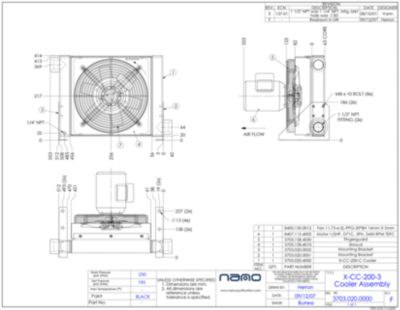

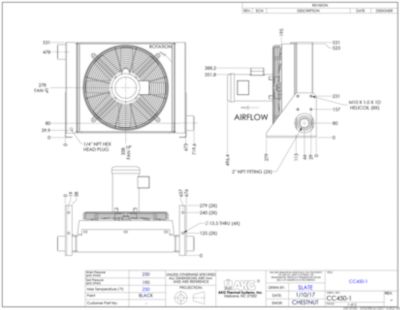

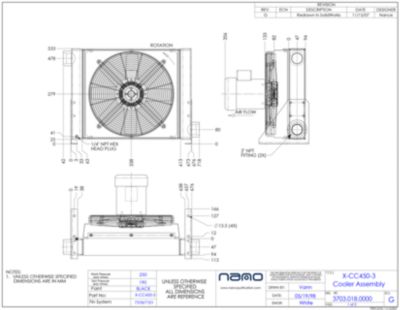

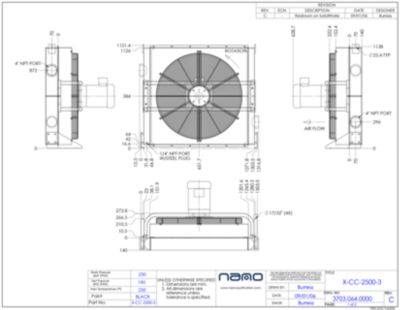

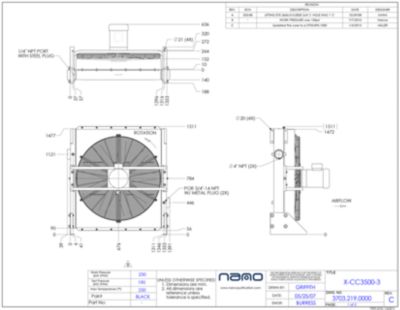

- General Arrangement Drawings

Features

Available 7 motor configurations to meet all application needs

Heresite core for corrosion protection, water separator for removing condensate

Specifications of Our Models

Specifications |

|

|---|---|

Maximum working pressure |

250 psi |

Maximum working temperature |

250°F |

Cooler material |

aluminum |

Shroud material |

powder painted steel |

Fan guard material |

zinc plated steel |

Fan blade material |

polypropylene blades/aluminum hub |

Mounting brackets |

powder painted steel |

ROTARY COMPRESSOR |

||

|---|---|---|

Air Compressor |

Internal Air Flow |

Recommended X-CC Model |

Horsepower |

Maximum cfm |

|

20 hp |

113 |

X-CC 100 |

25-40 hp |

245 |

X-CC 200 |

50-75 hp |

539 |

X-CC450 |

100-125 hp |

785 |

X-CC 600 |

150-200 hp |

1569 |

X-CC 1000 |

225-350 hp |

2300 |

X-CC 1600 |

400-500 hp |

3016 |

X-CC 2000 |

550-700 hp |

4316 |

X-CC 2500 |

750-1000 hp |

4800 |

X-CC 3500 |

PISTON COMPRESSOR |

||

|---|---|---|

Air Compressor |

Internal Air Flow |

Recommended X-CC Model |

Horsepower |

Maximum cfm |

|

20 hp |

83 |

X-CC 100 |

25-30 hp |

181 |

X-CC 200 |

40-70 hp |

432 |

X-CC450 |

75-100 hp |

638 |

X-CC 600 |

125-200 hp |

1256 |

X-CC 1000 |

225-300 hp |

2133 |

X-CC 1600 |

350-400 hp |

3400 |

X-CC 2000 |

400-500 hp |

4458 |

X-CC 2500 |

700-850 hp |

4800 |

X-CC 3500 |

MOISTURE SEPARATORS |

||

|---|---|---|

Aftercooler |

Separator |

Series Maximum Capacity |

X-CC 100 |

NF 0175 WS |

X-CC 100 |

X-CC 200 |

NF 0325 WS |

X-CC 200 |

X-CC450 |

NF 0700 WS |

X-CC450 |

X-CC 600 |

NF 0700 WS |

X-CC 600 |

X-CC 1000 |

NF 1250 WS |

X-CC 1000 |

X-CC 1600 |

NF 1500 WS |

X-CC 1600 |

X-CC 2000 |

NFE 3000 WS-ND |

X-CC 2000 |

X-CC 2500 |

NFE 3000 WS-ND |

X-CC 2500 |

X-CC 3500 |

NFE 3000 WS-ND |

X-CC 3500 |

Electrical Motor Data |

||||||||

|---|---|---|---|---|---|---|---|---|

Model |

HP RPM |

Motor Frame |

Single Phase |

Three Phase |

||||

Voltage |

Hz |

Full Load amps 230V |

Voltage |

Hz |

Full Load amps 230V |

|||

X-CC 100 |

⅓ 3450 |

IEC 63 |

115/230 |

60 |

2.6 |

208-230/460 190/380 |

60 50 |

1.1 |

X-CC 200 |

½ 3450 |

IEC 71 |

115/230 |

60 |

3.5 |

208-230/460 190/380 |

60 50 |

1.6 |

X-CC450 |

½ 1725 |

NEMA 56C |

115-230/460 |

60 |

4.0 |

208-230/460 |

60* |

2.0 |

X-CC 600 |

1 1725 |

NEMA 56C |

115-230/460 |

60 |

6.4 |

208/230/460 |

60* |

3.8 |

X-CC 1000 |

2 1725 |

NEMA 56C |

115/230 |

60 |

9.2 |

208-230/460 |

60* |

6.2 |

X-CC 1600 |

5 1725 |

NEMA 184TC |

230 |

60 |

23 |

208-230/460 |

60* |

13.2 |

X-CC 2000 |

7 ½ 1725 |

NEMA 213TC |

CF |

CF |

CF |

208-230/460 |

60* |

19.6 |

X-CC 2500 |

7 ½ 1725 |

NEMA 213TC |

CF |

CF |

CF |

208-230/460 |

60* |

19.6 |

X-CC 3500 |

10 1725 |

NEMA 213TC |

CF |

CF |

CF |

208-230/460 |

60* |

26.0 |

Air Motor Data |

||||

|---|---|---|---|---|

Model |

Air Pressure to Motor (psi) |

Motor Air Consumption (cfm) |

Air Motor Connection Size |

Fan RPM |

X-CC 100 |

30 |

10 |

¼” NPT |

3450 |

X-CC 200 |

60 |

17 |

¼” NPT |

3450 |

X-CC450 |

40 |

25 |

¼” NPT |

1725 |

X-CC 600 |

40 |

¼” NPT |

1725 |

|

X-CC 1000 |

60 |

70 |

½” NPT |

1725 |

X-CC 1600 |

60 |

150 |

1 ¼” NPT |

1725 |

X-CC 2000 |

80 |

200 |

1 ¼” NPT |

1725 |

X-CC 2500 |

80 |

200 |

1 ¼” NPT |

1725 |

X-CC 3500 |

100 |

240 |

1 ¼” NPT |

1725 |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.