These models offer high pressure filtration connected with high pressure 316 stainless steel pipe work and fittings included as standard (0.01 micron pre-filter and 1 micron after-filter).

Key Specs:

Flow Rate

42 to 918 scfm

Connection

1⁄2" to 3⁄4" NPT

Air Quality

ISO 8573.1:2010 Class 1, 2

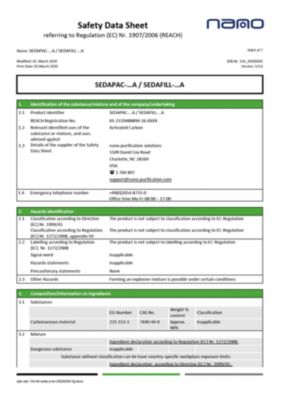

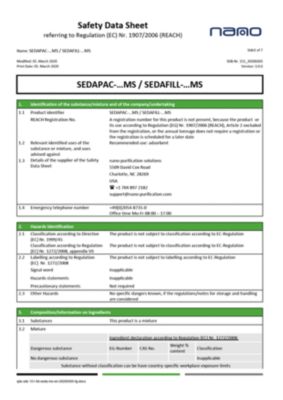

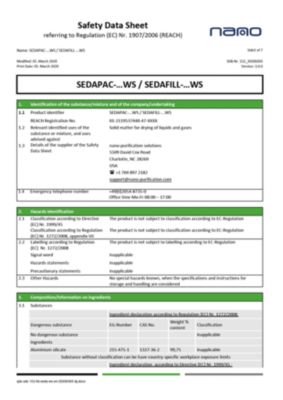

Product Documentation

- Brochures

- Material Safety Data Sheets

- User Guides

Features

The included rugged and reliable control valves provide excellent flow capacity and are designed for durability, ease of maintenance, and a long service life

The standard energy saving dew point control continually monitors outlet dew point for maximum energy savings

Specifications of Our Models

High-Pressure Desiccant Dryer Model |

Inlet & Outlet |

Rated Flow at 1450, 3625 or 5075 psig |

|---|---|---|

NPT |

scfm |

|

DHP / 100 (1450 psig) |

||

DHP5/100 |

½" |

42 |

DHP9/100 |

½” |

51 |

DHP12/100 |

½” |

90 |

DHP24/100 |

¾" |

167 |

DHP37/100 |

¾” |

252 |

DHP58/100 |

¾” |

442 |

DHP / 250 (3625 psig) |

||

DHP5/250 |

½" |

68 |

DHP9/250 |

½” |

82 |

DHP12/250 |

½” |

159 |

DHP24/250 |

¾" |

294 |

DHP37/250 |

¾” |

471 |

DHP58/250 |

¾” |

824 |

DHP / 350 (5075 psig) |

||

DHP5/350 |

½" |

88 |

DHP9/350 |

½” |

106 |

DHP12/350 |

½” |

177 |

DHP24/350 |

¾" |

309 |

DHP37/350 |

¾” |

500 |

DHP58/350 |

¾” |

918 |

Specifications |

DHC / 100 |

DHC / 350 |

|---|---|---|

Minimum operating pressure |

435 psig |

435 psig |

Maximum operating pressure |

1450 psig |

5075 psig |

Maximum particle size (ISO class) |

class 2 (1 micron) |

|

Maximum water content (ISO class) |

class 2 (-40°F pdp) |

|

Maximum oil content (ISO class) |

class 1 ( 0.01 ppm) |

|

Recommended operating temp range |

50 to 100°F |

|

Design operating temperature range |

35 to 140°F |

|

Power supply requirements |

120 & 240 VAC, 50/60 Hz |

|

Power consumption |

< 50 W |

|

Control panel protection |

IP 65 (NEMA 4X) |

|

Valve switching power (per valve) |

80 VA |

|

Materials of Construction |

||

|---|---|---|

Recommended operating temp range |

50 to 100°F |

|

Design operating temperature range |

35 to 140°F |

|

Power supply requirements |

120 & 240 VAC, 50/60 Hz |

|

Power consumption |

< 50 W |

|

Control panel protection |

IP 65 (NEMA 4X) |

|

Valve switching power (per valve) |

80 VA |

|

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.