Custom engineered hydrophobic and oleophobic borosilicate glass microfiber media repels oil and water for high efficiency filtration with minimal pressure drop

Key Specs:

Flow Rate

94 to 1882 scfm

Connection

¼” to 2” NPT

Filtration

25, 5, 1 & 0.01 micron, AC & WS

Product Documentation

- Brochures

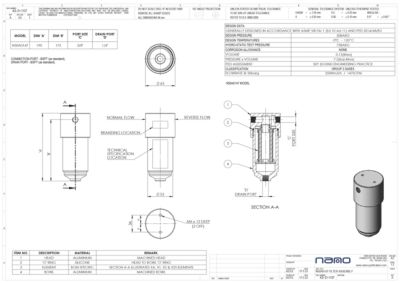

- GA Drawings

Features

Our design incorporates an innovative push-fit element design with dual o-ring seals to ensure optimum sealing and mechanical strength

Robust design with internal/external stainless steel support cores and glass filled nylon end caps

Specifications of our models

Filter Model |

Replacement Element |

Inlet & Outlet |

Rated Flow at 725 psig |

|---|---|---|---|

Part No. |

NPT |

scfm |

|

N50A 0094 (grade) |

E50HP 0094 (grade) |

¼” |

94 |

N50A 0147 (grade) |

E50HP 0147 (grade) |

⅜” |

147 |

N50A 0265 (grade) |

E50HP 0265 (grade) |

½” |

265 |

N50A 0324 (grade) |

E50HP 0324 (grade) |

¾” |

324 |

N50A 0492 (grade) |

E50HP 0492 (grade) |

1” |

492 |

N50A 0736 (grade) |

E50HP 0736 (grade) |

1½” |

736 |

N50A 1015 (grade) |

E50HP 1132 (grade) |

1½” |

1015 |

N50A 1132 (grade) |

E50HP 1132 (grade) |

2” |

1132 |

N50A 1882 (grade) |

E50HP 1882 (grade) |

2” |

1882 |

Specifications |

|

|---|---|

| Design operating pressure range |

0 to 725 psig |

Condensate drain (included) |

manual ball valve |

Filter housing material |

machined & die-cast aluminum |

Element Performance |

WS |

M25 |

M5 |

M1 |

M01 |

AC |

|---|---|---|---|---|---|---|

Particle removal |

- |

25 micron |

5 micron |

1 micron |

0.01 micron |

- |

Max oil carryover at 68°F |

25 ppm |

10 ppm |

5 ppm |

0.1 ppm |

0.01 ppm |

0.003 ppm |

Recommended operating temp range |

35 to 212°F |

35 to 212°F |

35 to 212°F |

35 to 212°F |

35 to 212°F |

35 to 77°F |

Design operating temperature range |

35 to 248°F |

35 to 248°F |

35 to 248°F |

35 to 248°F |

35 to 248°F |

35 to 248°F |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.