A closed water circuit and cycling chiller eco-friendly refrigerant boasts the lowest electricity consumption on the market

Key Specs:

Added Feature

Ferrous Water Circuit

Added Feature

Indoor or Outdoor Installations

Cooling Capacity

23,885 - 1,255,668 BTU /hr (2 - 104.6 tons)

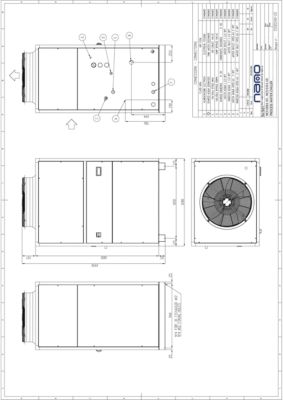

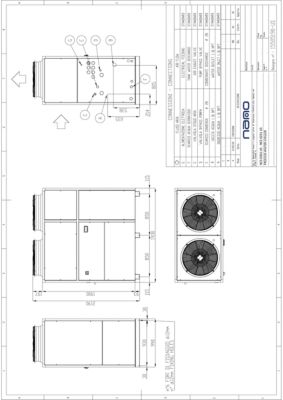

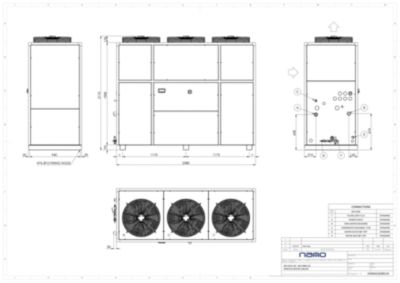

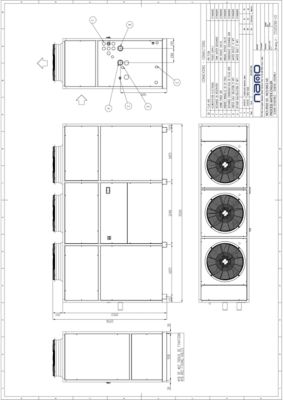

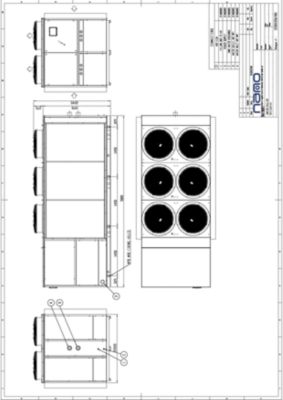

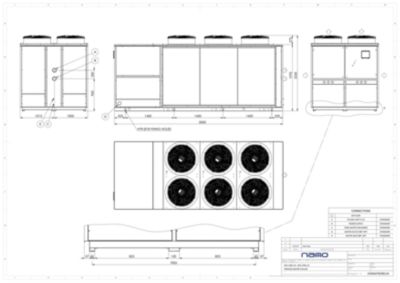

Product Documentation

- Brochures

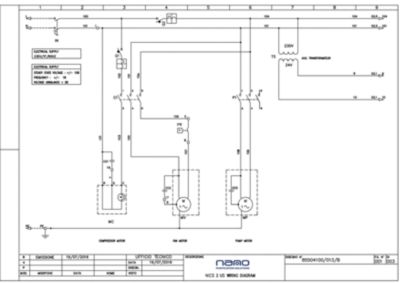

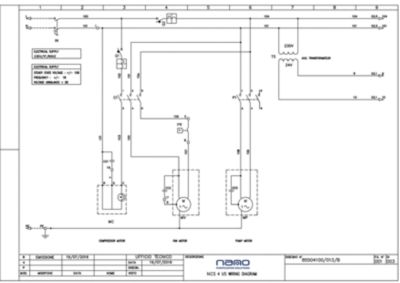

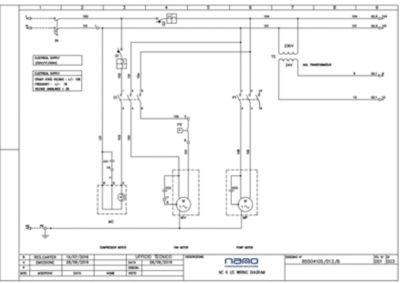

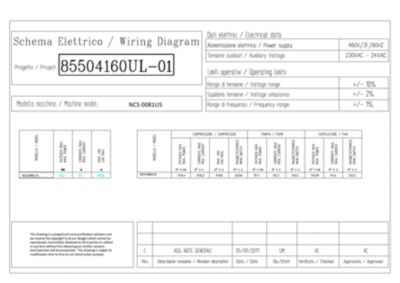

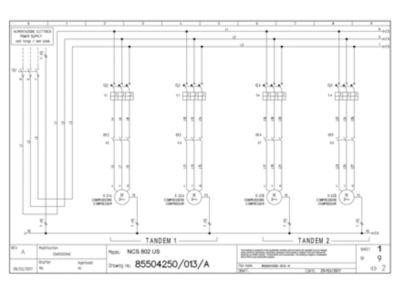

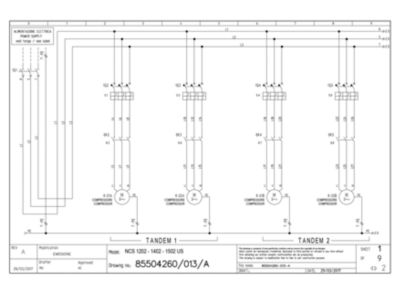

- Electrical Diagrams

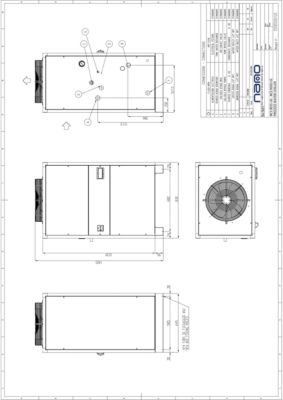

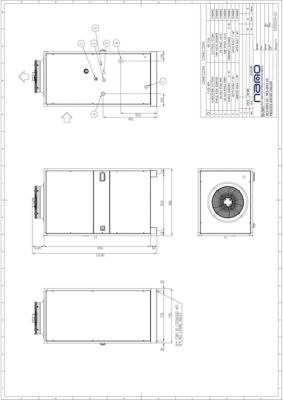

- General Arrangement Drawings

- Material Safety Data Sheets

- Pump Curves

- Service Manuals

- User Guides

- Worksheet

Features

These models include a CAREL microprocessor and Copeland ScrollTM compressors

Patented NO FROST evaporator is integral to the buffer vessel and protects against damage which can occur with improper setup or maintenance

Specifications of our models

Model |

Water |

Cooling Capacity |

Total Unit Installed Power |

Water |

Tank Capacity |

|

|---|---|---|---|---|---|---|

| NPT | BTU/h | tons | kW | hp | gal | |

| NCS 0015 US | ½” | 23,885 | 2.0 | 3.7 | 0.8 | 7.9 |

| NCS 0020 US | ½” | 32,893 | 2.7 | 4.8 | 0.8 | 7.9 |

| NCS 0031 US | 1” | 43,675 | 3.6 | 6.0 | 0.7 | 15.9 |

| NCS 0051 US | 1” | 56,983 | 4.7 | 7.9 | 0.7 | 15.9 |

| NCS 0061 US | 1” | 65,854 | 5.5 | 8.9 | 0.7 | 42.3 |

| NCS 0081 US | 1½” | 73,702 | 6.1 | 9.4 | 1.5 | 42.3 |

| NCS 0101 US | 1½” | 100,999 | 8.4 | 12.7 | 1.5 | 42.3 |

| NCS 0121 US | 1½” | 123,520 | 10.3 | 15.6 | 1.5 | 42.3 |

| NCS 0151 US | 1½” | 146,040 | 12.2 | 17.9 | 1.5 | 42.3 |

| NCS 0201 US | 1½” | 201,999 | 16.8 | 24.3 | 2.9 | 76.6 |

| NCS 0251 US | 1½” | 247,039 | 20.6 | 31.1 | 2.9 | 76.6 |

| NCS 0351 US | 2” | 292,079 | 24.3 | 35.7 | 2.9 | 121.5 |

| NCS 0401 US | 2” | 335,755 | 28.0 | 42.3 | 4.0 | 121.5 |

| NCS 0502 US | 3” | 379,430 | 31.6 | 48.7 | 4.0 | 132.1 |

| NCS 0602 US | 3” | 477,700 | 39.8 | 59.9 | 5.4 | 132.1 |

| NCS 0652 US | 3” | 552,767 | 46.1 | 69.9 | 5.4 | 132.1 |

| NCS 0802 US | 3” | 671,510 | 56.0 | 83.5 | 5.4 | 243.0 |

| NCS 1002 US | 3” | 758,860 | 63.2 | 93.1 | 10.1 | 243.0 |

| NCS 1202 US | 3” | 955,400 | 79.6 | 116.5 | 10.1 | 264.2 |

| NCS 1402 US | 4” | 1,105,534 | 92.1 | 139.9 | 10.1 | 264.2 |

| NCS 1502 US | 4” | 1,255,668 | 104.6 | 151.9 | 10.1 | 264.2 |

| Specifications | NCS 0015 - NCS 1502 | |

|---|---|---|

| Power supply | voltage/phases | 460V/3Ph/60Hz |

| Refrigerant | type | R410A |

| Inlet water temperature | minimum | 32°F |

| maximum | 86°F | |

| Outlet water temperature | minimum | 32°F |

| maximum | 68°F | |

| Ambient temperature | minimum | 23°F |

| maximum | 106°F | |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.