Product documentation

- Brochures

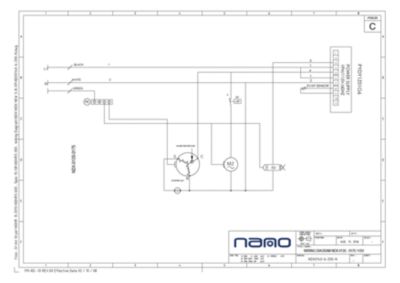

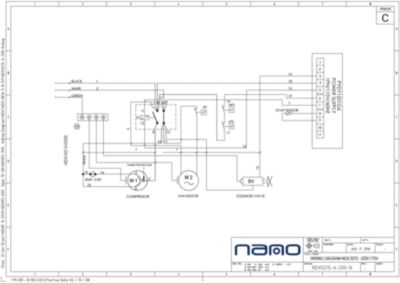

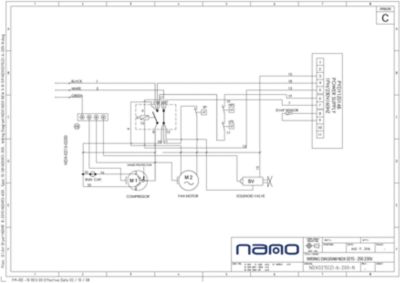

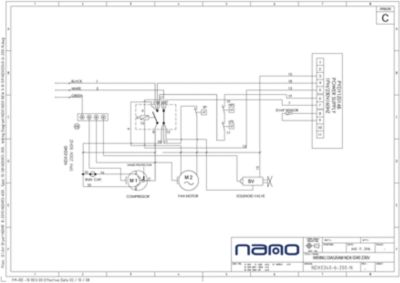

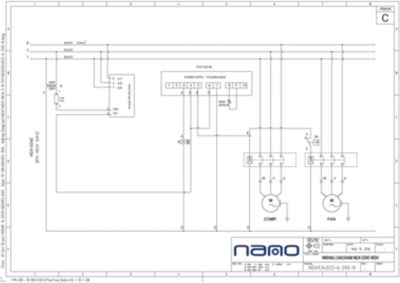

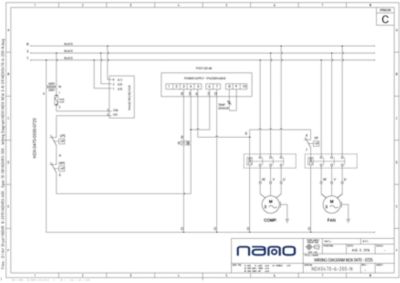

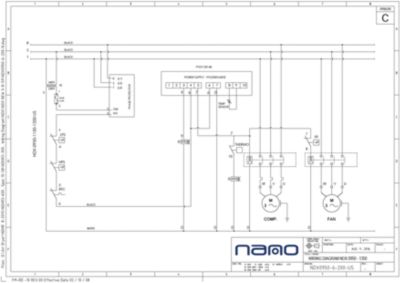

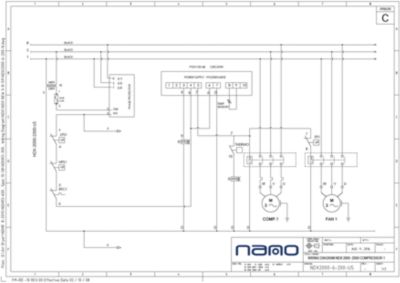

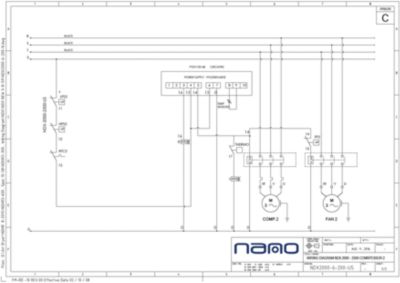

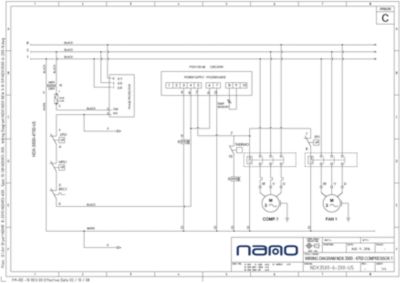

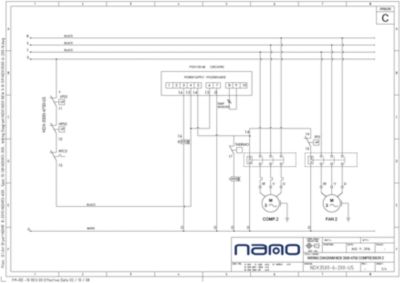

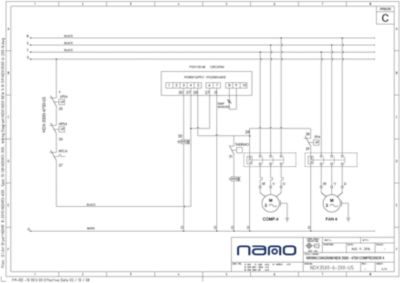

- Electrical Diagrams

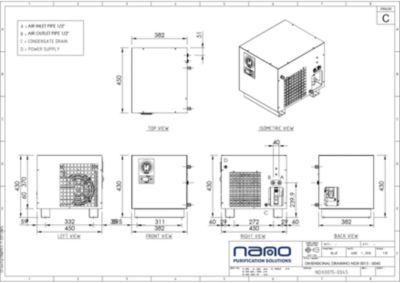

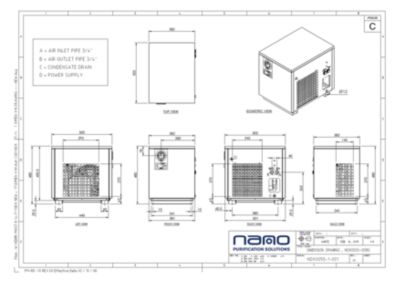

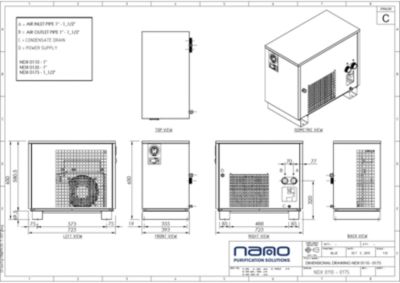

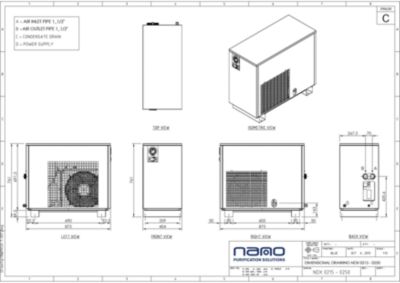

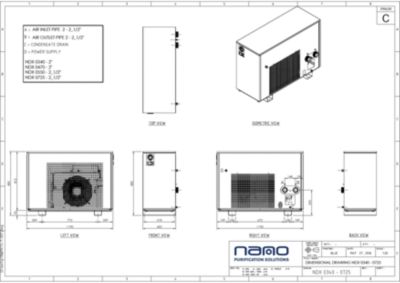

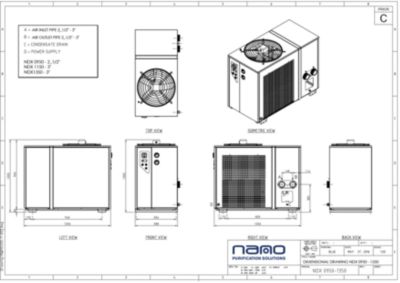

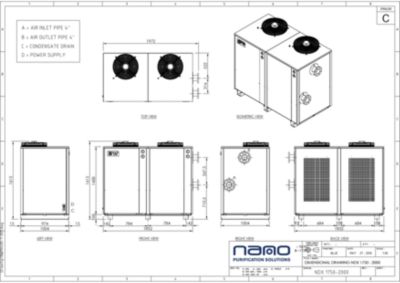

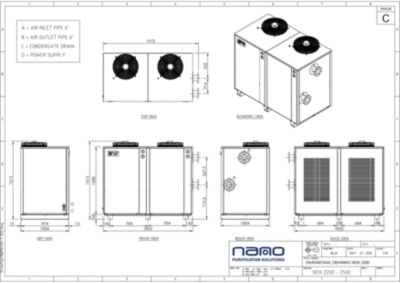

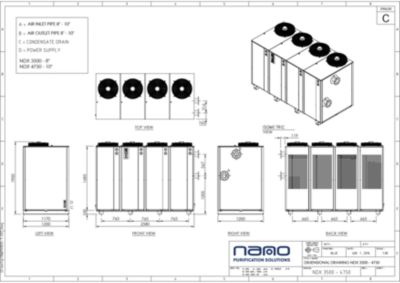

- General Arrangement Drawings

- Material Safety Data Sheets

- User Guides

Technical Data by Model

Dryer Model |

Inlet & Outlet |

Flow Rate at 100 psig | Absorbed Power |

Power Supply (V/Ph/60Hz) |

||

|---|---|---|---|---|---|---|

NPT/FLG |

scfm |

kW |

115/1 |

230/1 |

460/3 |

|

½” |

15 |

0.22 |

• |

|||

½” |

20 |

0.23 |

• |

|||

½” |

30 |

0.24 |

• |

|||

½” |

45 |

0.25 |

• |

|||

¾” |

55 |

0.47 |

• |

|||

¾” |

85 |

0.49 |

• |

|||

1” |

110 |

0.92 |

• |

|||

1” |

135 |

0.92 |

• |

|||

1 ½” |

175 |

0.96 |

• |

|||

1 ½” |

215 |

0.94 |

• |

|||

1 ½” |

250 |

1.05 |

• |

|||

2” |

250 |

1.47 |

• |

|||

NDX 0340 |

2” |

340 |

1.47 |

|||

2” |

470 |

2.50 |

• |

|||

2 ½” |

550 |

2.60 |

• |

|||

2 ½” |

725 |

3.46 |

• |

|||

2 ½” |

950 |

3.60 |

• |

|||

3” |

1150 |

5.04 |

• |

|||

3” |

1350 |

6.54 |

• |

|||

4” Flg |

1750 |

7.20 |

• |

|||

4” Flg |

2000 |

7.20 |

• |

|||

6” Flg |

2500 |

13.08 |

• |

|||

8” Flg |

3500 |

14.40 |

• |

|||

10” Flg |

4750 |

26.16 |

• |

|||

Specifications |

NDX 0015 to NDX 0725 |

NDX 0950 to NDX 2000 |

|---|---|---|

Design operating pressure range |

0 to 232 psig |

0 to 189 psig |

Maximum inlet temperature |

158°F |

|

Maximum ambient temperature |

110°F to 122°F depending on refrigerant (contact nano support for details) |

|

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.