Product Documentation

- Brochures

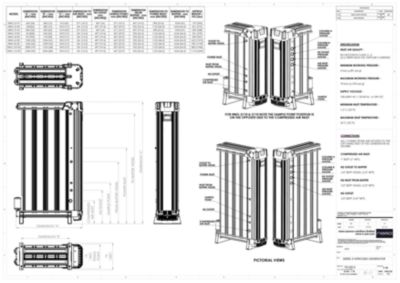

- General Arrangement Drawings

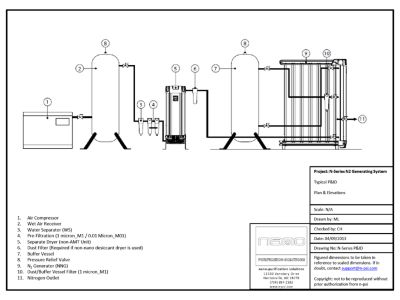

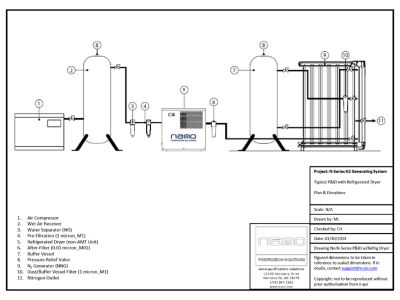

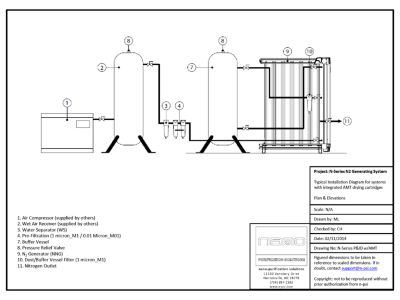

- Installation Diagrams

- Material Safety Data Sheets

- User Guides

Technical Data by Model

Generator Model |

Rated Outlet Flow at 100 psig |

Nitrogen Purity at the Outlet (Maximum Oxygen Content) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

99.999% |

99.995% |

99.99% |

99.75% |

99.95% |

99.9% |

99.5% |

99% |

98% |

97% |

96% |

95% |

||

NNG 1110 |

scfh |

21 |

35 |

56 |

67 |

74 |

88 |

134 |

159 |

194 |

230 |

265 |

282 |

NNG 2110 |

scfh |

42 |

71 |

113 |

134 |

148 |

177 |

268 |

318 |

388 |

459 |

530 |

565 |

NNG 3110 |

scfh |

64 |

106 |

169 |

201 |

222 |

265 |

403 |

477 |

583 |

689 |

794 |

847 |

NNG 2130 |

scfh |

71 |

134 |

191 |

254 |

304 |

318 |

501 |

636 |

777 |

918 |

1024 |

1130 |

NNG 3130 |

scfh |

106 |

201 |

286 |

381 |

455 |

477 |

752 |

953 |

1165 |

1377 |

1536 |

1695 |

NNG 4130 |

scfh |

141 |

268 |

381 |

508 |

607 |

636 |

1003 |

1271 |

1554 |

1836 |

2048 |

2260 |

NNG 6130 |

scfh |

212 |

403 |

572 |

763 |

911 |

953 |

1504 |

1907 |

2330 |

2754 |

3072 |

3390 |

NNG 8130 |

scfh |

268 |

510 |

725 |

966 |

1154 |

1208 |

1905 |

2415 |

2952 |

3489 |

3891 |

4294 |

NNG 10130 |

scfh |

328 |

624 |

887 |

1182 |

1412 |

1478 |

2332 |

2955 |

3612 |

4269 |

4762 |

5254 |

NNG 12130 |

scfh |

381 |

725 |

1030 |

1373 |

1640 |

1716 |

2708 |

3432 |

4195 |

4958 |

5530 |

6102 |

Specifications |

|

|---|---|

Design operating pressure range |

87 - 145 psig |

Design operating temperature range |

50 - 104°F |

Maximum inlet particulate |

0.1 micron |

Maximum inlet dew point |

80°F PDP |

Maximum inlet oil content |

0.01 ppm |

Maximum outlet dew point |

-40°F PDP |

Supply voltage |

120 - 240 VAC (50 or 60Hz) or 24VDC |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.