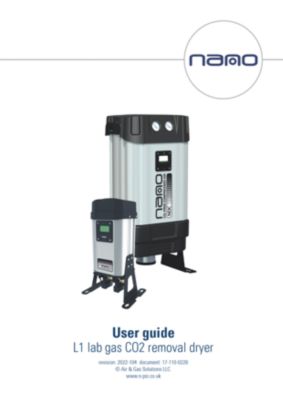

These models were developed for laboratories, so these units require no bench space, can be wall mounted, and ensure quiet operation with a novel exhaust silencer.

Key Specs:

Flow Rate

2.5 to 200 I/min

Connection

⅜” to 1” BSPP

Air Quality

CO2 levels of less than 1 ppm

Product Documentation

- Brochures

- Certificates

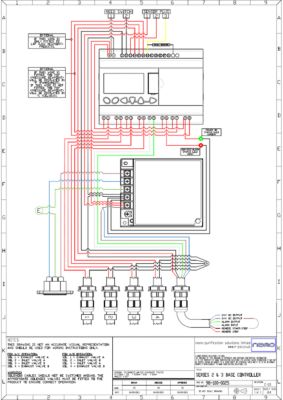

- Electrical Diagrams

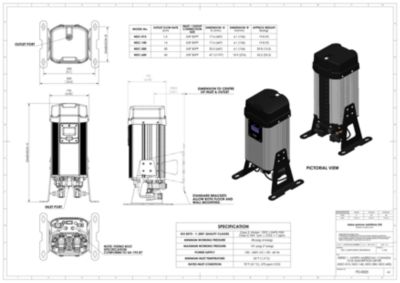

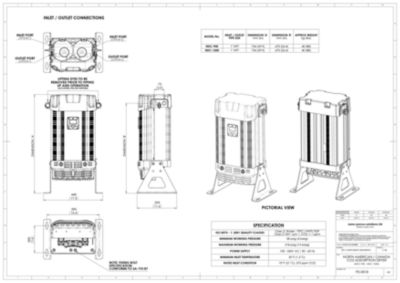

- General Arrangement Drawings

- Material Safety Data Sheets

- Service Intervals

- Spare Parts Guide

- User Guides

Features

Each model requires less than 15 minutes for maintenance due to unique factory built-in filtration and adsorption cartridges.

PLC Controller with clear text display as standard.

Specifications of Our Models

CO2 Removal Dryer Model |

Recommended Filtration |

Inlet & Outlet |

Inlet Air Flow at 7 barg | Outlet Gas Flow |

|---|---|---|---|---|

Part no. |

BSPP |

l/min |

l/min |

|

NDC 015 |

GFNB 0025 |

3/8” |

2.5 |

1.5 |

NDC 050 |

GFNB 0025 |

⅜” |

8.3 |

5.0 |

NDC 140 |

GFNB 0025 |

3/8” |

25 |

15 |

NDC 300 |

GFNB 0025 |

⅜” |

50 |

30 |

NDC 600 |

GFNB 0025 |

½” |

100 |

60 |

NDC 900 |

GFNB 0050 |

1” |

150 |

90 |

NDC 1200 |

GFNB 0050 |

1” |

200 |

120 |

Outlet Gas Quality |

Standard |

Optional |

|---|---|---|

Maximum CO2 content |

1 ppm |

- |

Maximum pressure dew point |

-70°C |

- |

Maximum particulate size |

1 micron |

0.01 micron |

Maximum oil content |

- |

0.003 ppm |

Specifications |

||

|---|---|---|

Design operating pressure range |

4 to 12 barg |

|

Recommended operating temperature range |

1.5 to 20°C |

|

Power supply requirements |

85 to 264V AC (50/60Hz) |

|

Maximum noise level (during purge) |

60 dBa |

|

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.