These models can reduce power consumption up to 80% vs non-cycling dryers.

Key Specs:

Flow Rate

2600 to 8450 scfm

Connection

6” to 8” Flg

Air Quality

ISO 8573.1:2010 Class 4

Product Documentation

- Brochures

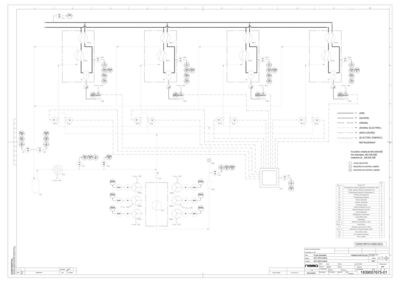

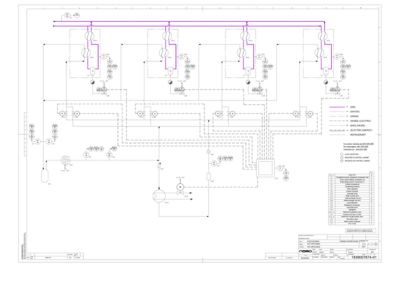

- Electrical Diagrams

- Flow Diagrams

- General Arrangement Drawings

- Installation Diagrams

- Material Safety Data Sheets

- User Guides

- Worksheets

Features

Each unit maintains a constant dewpoint even as the compressed air flow rate fluctuates.

Uses zero ozone depletion and low CO2 emissions refrigerant.

Specifications of Our Models

Variable Speed Refrigerated Dryer Model |

Inlet & Outlet |

Rated Flow at 100 psig |

Pressure Drop |

Absorbed Power |

Power Supply |

|---|---|---|---|---|---|

Flg |

scfm |

psi |

kW |

460/60/3 |

|

Aircooled |

|||||

6” |

2600 |

2.6 |

9.9 |

• |

|

6” |

3150 |

2.6 |

10.5 |

• |

|

6” |

3700 |

2.2 |

11.3 |

• |

|

6” |

4200 |

2.8 |

14.2 |

• |

|

6” |

5050 |

3.9 |

19.1 |

• |

|

8” |

6350 |

2.8 |

23.9 |

• |

|

8” |

8450 |

2.8 |

28.1 |

• |

|

Watercooled |

|||||

6” |

2600 |

2.6 |

6.1 |

• |

|

6” |

3150 |

2.6 |

6.6 |

• |

|

6” |

3700 |

2.2 |

7.5 |

• |

|

6” |

4200 |

2.8 |

8.3 |

• |

|

6” |

5050 |

3.9 |

12.8 |

• |

|

8” |

6350 |

2.8 |

14.4 |

• |

|

8” |

8450 |

2.8 |

19.7 |

• |

|

Specifications |

|

|---|---|

Design operating pressure range |

30 to 203 psig |

Maximum inlet temperature |

158°F |

Design ambient temperature |

45 to 114.8°F |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.

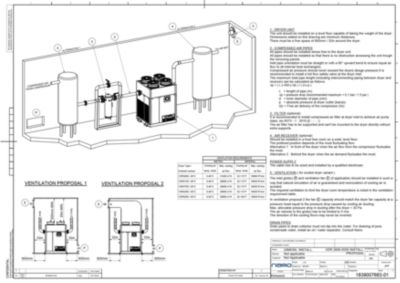

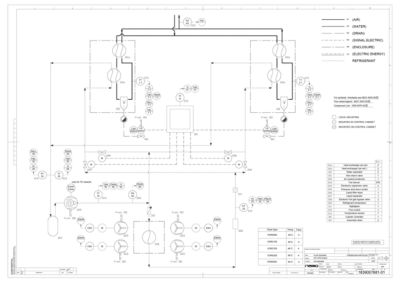

![R6 VDR 2600-5050 (aircooled) [Imperial] - General Arrangement (GA) Drawing The ga drawing for the aircooled R6 VDR 2600-5050 models](http://atlascopco.scene7.com/is/image/atlascopco/R6-VDR-2600-5050-aircooled-ga-general-arrangement-drawing-imperial-variable-speed-ref-931WbMUoQU)

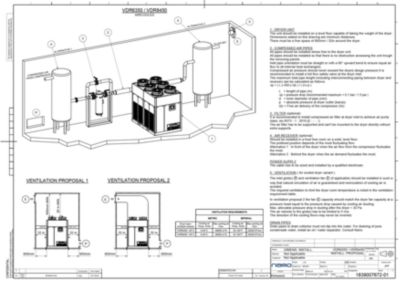

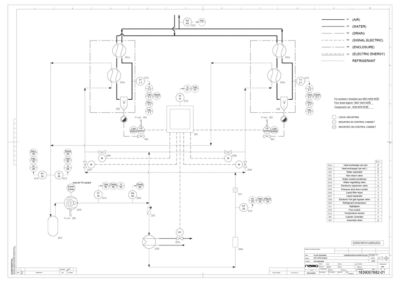

![R6 VDR 2600-5050 (watercooled) [Imperial] - General Arrangement (GA) Drawing The ga drawing for the watercooled R6 VDR 2600-5050 models](http://atlascopco.scene7.com/is/image/atlascopco/R6-VDR-2600-5050-watercooled-ga-general-arrangement-drawing-imperial-variable-speed-r-BfpHsTyeIs)

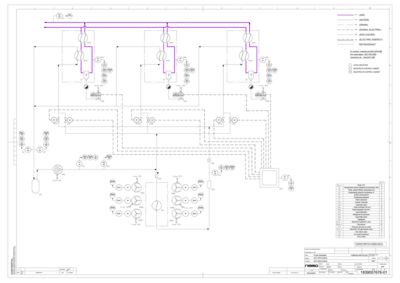

![R6 VDR 6350-8450 (aircooled) [Imperial] - General Arrangement (GA) Drawing The ga drawing for the aircooled R6 VDR 6350-8450 models](http://atlascopco.scene7.com/is/image/atlascopco/R6-VDR-6350-8450-aircooled-ga-general-arrangement-drawing-imperial-variable-speed-ref-jA7Tb4WobR)

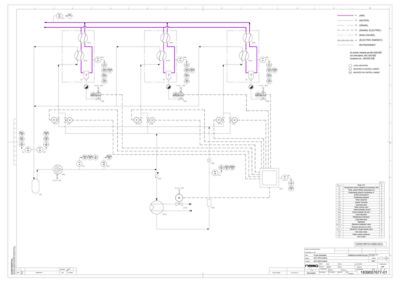

![R6 VDR 6350-8450 (watercooled) [Imperial] - General Arrangement (GA) Drawing The ga drawing for the watercooled R6 VDR 6350-8450 models](http://atlascopco.scene7.com/is/image/atlascopco/R6-VDR-6350-8450-watercooled-ga-general-arrangement-drawing-imperial-variable-speed-r-jZPh0SVD41)