Product Documentation

- Brochures

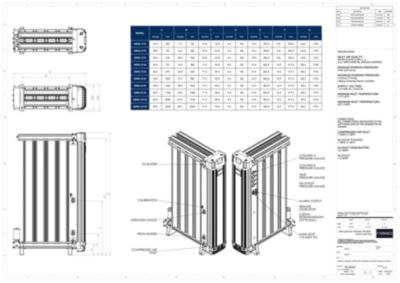

- General Arrangement Drawings

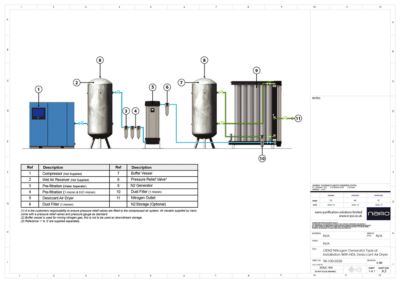

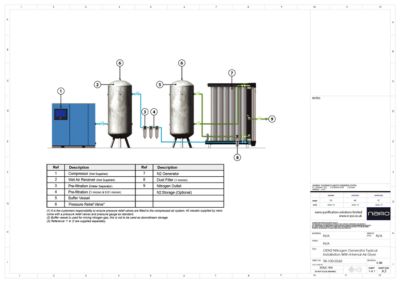

- Installation Diagram

- Material Safety Data Sheets

- User Guides

Technical Data by Model

Generator Model |

Rated Outlet Flow at 100 psig |

Nitrogen Purity at the Outlet (Maximum Oxygen Content) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

99.999% |

99.995% |

99.99% |

99.75% |

99.95% |

99.9% |

99.5% |

99% |

98% |

97% |

96% |

95% |

||

GEN2 1110 |

scfh |

49 |

71 |

81 |

95 |

109 |

127 |

184 |

205 |

258 |

293 |

335 |

364 |

GEN2 2110 |

scfh |

99 |

141 |

162 |

191 |

219 |

254 |

367 |

410 |

516 |

586 |

671 |

727 |

GEN2 3110 |

scfh |

148 |

212 |

244 |

286 |

328 |

381 |

551 |

614 |

773 |

879 |

1006 |

1091 |

GEN2 2130 |

scfh |

180 |

254 |

297 |

353 |

403 |

466 |

667 |

742 |

932 |

1070 |

1218 |

1324 |

GEN2 3130 |

scfh |

270 |

381 |

445 |

529 |

604 |

699 |

1001 |

1112 |

1398 |

1605 |

1828 |

1986 |

GEN2 4130 |

scfh |

360 |

509 |

593 |

706 |

805 |

932 |

1335 |

1483 |

1865 |

2140 |

2437 |

2649 |

GEN2 6130 |

scfh |

540 |

763 |

890 |

1058 |

1208 |

1395 |

2002 |

2225 |

2797 |

3210 |

3655 |

3973 |

GEN2 8130 |

scfh |

720 |

1017 |

1187 |

1411 |

1610 |

1865 |

2670 |

2966 |

3729 |

4280 |

4873 |

5297 |

GEN2 110130 |

scfh |

828 |

1170 |

1365 |

1623 |

1852 |

2144 |

3070 |

3411 |

4289 |

4922 |

5604 |

6092 |

GEN2 12130 |

scfh |

962 |

1358 |

1584 |

1884 |

2150 |

2489 |

3564 |

3960 |

4979 |

5714 |

6506 |

7072 |

Specifications |

|

|---|---|

Design operating pressure range |

87 - 175 psig |

Design operating temperature range |

41-122°F |

Maximum inlet particulate |

0.1 micron |

Maximum inlet dew point |

80°F PDP |

Maximum inlet oil content |

0.01 ppm |

Maximum outlet dew point |

-40°F |

Supply voltage |

100 - 240 VAC (50 or 60Hz) or 24VDC |

(1) This information is for general information purposes only. For additional technical specifications, refer to the product brochure, technical data sheets, and/or user guides. Technical specifications are subject to change.